Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Safety standards affect all parts of city infrastructure. Manhole covers are important in streets and sidewalks. They also matter in drainage systems. These covers keep drains safe and protect people from danger. Safety standards for manhole covers stop injuries and keep drains safe. If manhole cover standards are not good, cities face problems. Good safety standards help cities stay healthy and strong. Standards for manhole covers also keep people safe in drainage areas. Cities need strong manhole cover standards in every drainage place. Safety in drainage systems is very important.

Good safety rules for manhole covers stop accidents. Covers must fit well and have small holes. They need locks and bright colors to help people see them.

Manhole covers should be very strong. They must hold heavy things like cars and trucks. There are different types for sidewalks, roads, and airports. This keeps people and vehicles safe.

Checking manhole covers often helps find problems early. It stops rust and damage. This makes covers last longer. Cities save money and avoid big problems.

Using covers made from rust-proof materials helps the environment. It also keeps drains working during storms.

Following safety laws and using smart technology in covers helps cities stay safe. It stops theft and keeps city systems working well.

Safety standards for manhole covers help stop accidents in cities. These rules lower the chance of tripping, falling, or people getting in without permission. Manhole covers need to fit tight and be even with the ground. If covers are loose or gone, people can trip or fall. Cars and bikes can also get damaged. ADA-compliant grates have small slots. They are put in places so wheelchairs, canes, and walkers do not get stuck. Heel-proof grates have even smaller holes. These stop high heels from getting caught. These features help keep everyone safe, including people with disabilities.

Workers check manhole covers often to keep them safe. They look for loose covers, rust, and cracks every three months. Cleaning takes away dirt and rust. This helps stop slips and keeps the area safe. Repairs like filling cracks and adding anti-rust paint keep covers strong. Bolts and locks stop covers from moving or being stolen. These things also stop people from getting in when they should not.

Safety standards say manhole covers need clear labels. Words like “HOLE” or “COVER” warn people about danger. Bright paint on the edges helps people see covers at night. OSHA rules say workers must put up barriers after taking off a cover. This stops people from falling into open manholes. These steps protect workers and everyone else.

| Safety Standard Aspect | Purpose | Accident Type Prevented |

|---|---|---|

| Limiting infiltration hole size | Stops bike wheels from getting stuck | Wheel entrapment accidents involving bicycles |

| Hole orientation | Stops wheels from catching | Trips, falls, and wheel entrapment |

| Secure installation with tight fit and bolts | Stops covers from moving or leaving gaps | Falls of pedestrians and vehicles, vehicle damage |

Strong manhole covers made from ductile iron or steel are very tough. These covers meet strict safety rules. They do not crack or break easily. This helps stop accidents. Using strong covers in busy places keeps everyone safe.

For more about safe products, visit the [manhole covers product page] or see our [company overview].

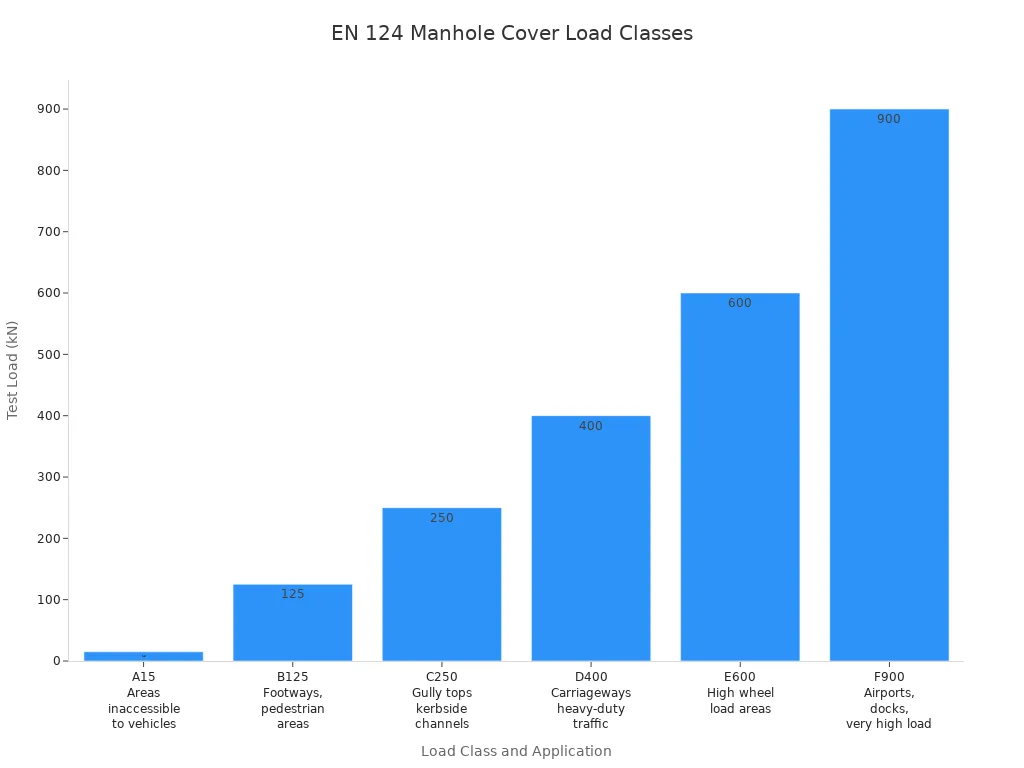

Manhole covers must be strong enough for city safety. Engineers pick covers based on how much weight they must hold. Covers in walking areas need less strength than those on roads with trucks. The European EN 124 standard sorts covers by how much weight they can take. This helps cities pick the right cover for each place.

| Group | Application Area Description | Minimum Load Class | Test Load (kN) |

|---|---|---|---|

| 1 | Areas inaccessible to motor vehicles | A15 | 15 |

| 2 | Footways, pedestrian areas | B125 | 125 |

| 3 | Gully tops in kerbside channels of roads | C250 | 250 |

| 4 | Carriageways of roads with heavy-duty traffic | D400 | 400 |

| 5 | Areas imposing high wheel loads | E600 | 600 |

| 6 | Airports, docks (very high wheel load) | F900 | 900 |

Good manhole covers must meet or beat these standards. Ductile iron covers are popular because they are strong and last long. They do not rust easily. These covers work well in places with lots of cars and trucks. Engineers test covers by putting weight on them again and again. They check if the covers bend or break.

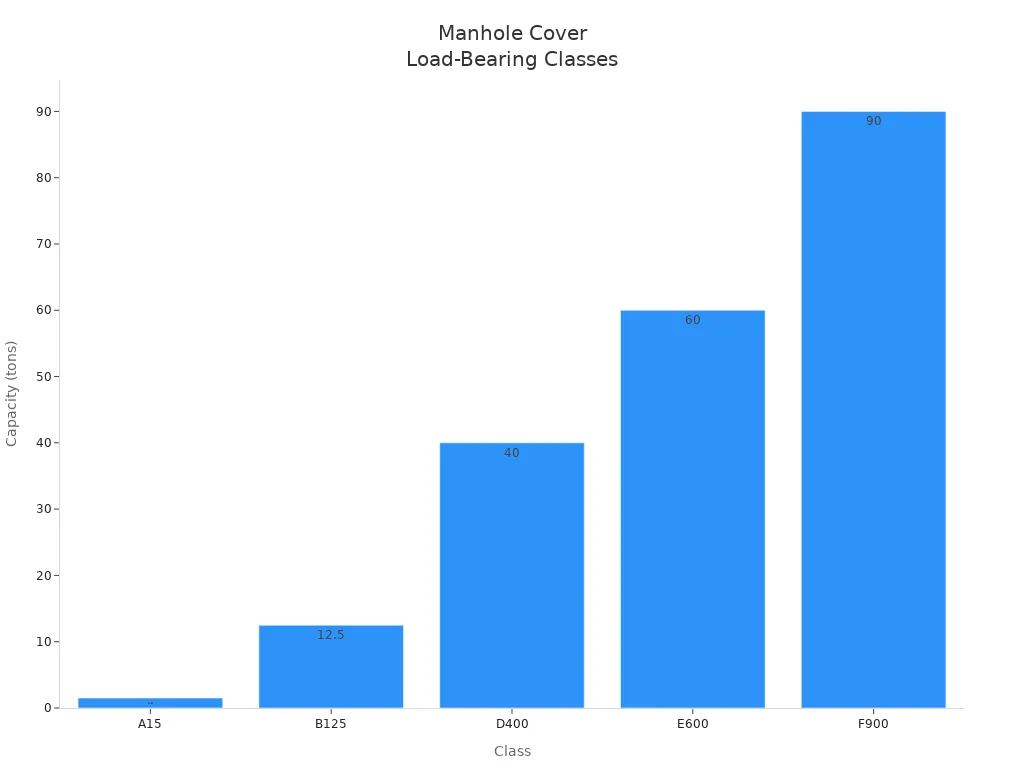

| Class | Load-Bearing Capacity | Typical Usage Areas |

|---|---|---|

| A15 | Up to 1.5 tons | Pedestrian areas, residential pathways |

| B125 | Up to 12.5 tons | Pedestrian areas, residential areas with slow vehicles |

| D400 | Up to 40 tons | Urban areas, industrial areas with moderate-speed traffic |

| E600 | Up to 60 tons | High-speed traffic areas, highways, ports, airports |

| F900 | Up to 90 tons | Extremely heavy traffic areas, highways, ports, airports |

Good manhole covers must also meet other world standards. Some are AASHTO M306 in North America and ASTM A48 for ductile iron. These rules say how strong, safe, and tough covers must be. Covers must pass tests for impact and wear. Some must last through 500,000 weight cycles. Galvanized coatings stop rust for over 25 years. This keeps covers safe and working for a long time.

| Standard / Specification | Region / Application | Key Quality & Durability Requirements |

|---|---|---|

| EN124 | Europe | Load classes A15 to F900; anti-slip surfaces; ductile iron material; dimensional tolerances; compliance marking |

| AASHTO M306 | North America | Material and performance requirements for manhole covers; compatibility with ASTM standards |

| ASTM A48 | International | Grey iron castings and ductile iron covers; impact resistance; material robustness |

| ASTM A36 | International | Steel riser rings; galvanization per ASTM A123; material composition and strength |

| Performance Benchmarks | International | Fatigue resistance minimum 500,000 load cycles; slip resistance ≥75 PTV under wet conditions |

| Quality Assurance | International | Mill test reports; batch-wise load testing; ISO 9001 certification; 10-year structural warranties |

If a manhole cover is not strong enough, it can crack or break. This is dangerous for cars and people. Broken covers can block traffic and hurt people. Checking covers often, putting them in right, and using strong materials help stop these problems. Training workers and following safety rules make sure covers are strong and safe.

To learn more about ductile iron manhole covers and their uses, visit our [ductile iron manhole covers page] or see our [water grates product page].

Manhole covers help keep people healthy in cities. They stop people from touching dangerous liquids in drains. Many covers have surfaces that do not slip and can resist chemicals. Workers stay above the liquids when they clean or fix things. This keeps bad stuff from spreading and reaching people. Some manhole covers work with berm systems for cleaning up spills. They help stop mixing of harmful materials. By keeping workers and people away from dangerous things, manhole covers help drains work well and keep everyone healthy.

Manhole covers in drainage channels:

Give workers a safe place to stand.

Stop people from touching dangerous liquids.

Lower the chance of spreading harmful stuff.

Help with emergency cleanups.

Keep drains clean and safe.

To learn more about manhole covers and how they help health, visit the manhole covers product page or read about customized smart manhole covers.

Manhole covers in drains help protect nature. Covers made from composite materials do not rust. This means less pollution and less waste from replacing covers. Lighter covers use less fuel when moved and put in place. Composite covers need less energy to make than metal ones. This helps lower pollution even more. Some covers reflect sunlight and do not get as hot. This helps keep cities cooler and saves energy. Covers that can be recycled help keep trash out of landfills. They also help reuse materials. Manhole covers keep water moving and stop drains from getting blocked. Good covers help cities handle rainwater and keep rivers and lakes safe.

Groups make rules for manhole covers to keep them strong and safe. Inspections check that covers follow all safety rules. When cities use these standards, they stop accidents and protect people and nature.

To see more about water grates and how they help the environment, visit the water grate page or read about inspection manhole covers.

Cities need manhole covers to work well everywhere. These covers keep drains and underground pipes safe from harm. They also stop people from getting in when they should not. Ductile iron manhole covers are strong. They can hold up heavy cars and bad weather. These covers last a long time. This helps the city keep working during storms or busy times. Composite covers do not rust. This helps drains work better and lowers the chance of problems.

Smart manhole covers use sensors and IoT technology. They help cities watch for weight, heat, and if someone opens the cover. This smart tech makes city systems safer and better. Cities can find problems fast and stop dangers. This keeps drains clear and roads open. Big projects in places like the UK show that good manhole covers help traffic move and help the economy grow. To learn more about smart covers, visit the customized smart manhole cover page.

Good manhole covers keep roads safe, stop water from building up, and help drains work well.

Taking care of manhole covers helps them last longer and work better. Checking covers often helps find cracks, rust, or if they are not lined up right. How often covers get cleaned depends on where they are. Light-use areas need cleaning every 1-3 months. Busy drains may need cleaning every week. Both ductile iron and composite covers should be cleaned gently. Sweeping or using low water pressure helps stop damage and rust.

A good plan for care includes:

Checking for cracks, rust, and if covers can hold weight.

Cleaning with soft soap and not using strong chemicals.

Putting on coatings to stop rust and keep covers strong.

Looking at the supports and drains to make sure nothing is blocking them.

These steps help save money on repairs and keep things working well. Manhole covers that are hard to steal and very strong help stop sudden problems and money loss. Cities that do these things have fewer problems and better city systems. To learn more about checking covers and care, visit the inspection manhole cover page or the company overview.

Manhole covers in cities must follow strict laws. City planners and engineers use standards to keep drains safe. OSHA makes rules for safety in public places. EN 124, AASHTO M306, and ASTM A48 are important standards. These rules help pick covers that fit the traffic in each area. EN 124 sorts covers by weight class. This helps choose covers for busy roads or quiet paths. The ADA gives rules for hole size and direction. This keeps wheelchair users safe and stops wheels from getting stuck.

Certified manhole covers have marks that show they meet safety rules. These marks help planners avoid legal trouble. Using good materials and designs stops rust and keeps covers strong. Regular checks and care, as shown on the inspection manhole cover page, help cities follow the rules and save money. Following standards lowers accidents and keeps drains working well. Planners and engineers have less risk and help cities grow safely.

Strong standards for manhole covers help everyone in the city. People have fewer accidents because slip-resistant covers stop falls. Locking systems stop people from getting in or damaging covers. This keeps drains and streets safe. Workers do their jobs faster and safer with light, rust-proof covers made from fiberglass composites. These covers last longer and do not rust, so drains stay open.

Cities use bright colors or shiny coatings on covers to help drivers see them. This lowers traffic accidents and helps at night. Real examples show these ideas work. New York switched iron covers for fiberglass ones. This made covers last longer and handle bad weather. Atlanta added locks to stop theft and damage. Pasadena uses safety systems to warn crews when covers move. Canadian companies use slip-proof coatings and bright colors to lower accidents. Tennessee groups put in locks to make covers safer and easier to care for.

Cities with strong manhole cover standards have safer streets, better drains, and stronger systems. These changes help cities grow and keep people healthy.

For more about best ways and products, visit the company overview or see the manhole covers product page.

Sometimes cities have problems when manhole covers are not safe. In one city, heavy rain made water move fast in drains. Weak manhole covers broke from the strong water. Cars fell into the holes. Some people got hurt. The city found out the old covers had rust. Rust made the covers weak. The drains did not work because the covers could not hold the weight. The city had to close roads and fix the broken parts. This story shows why strong manhole covers are needed for safety.

Another city had a problem with theft. Thieves stole manhole covers from drains. This left open holes on busy streets. People tripped and got hurt. The city learned covers without locks are easy to steal. When covers were gone, trash fell into the drains. This blocked the drains and caused floods. The city put in ductile iron manhole covers with locks. These new covers stopped stealing and made the city safer.

Unsafe manhole covers can cause accidents, blocked drains, and damage to city systems.

Some cities got better by using stronger manhole covers. In a big city, engineers picked ductile iron manhole covers for all drains. These covers do not rust and last a long time. The city had fewer accidents and less flooding. The drains worked better. Workers saw that the new covers needed less fixing. The city saved money and made things safer.

A company used composite manhole covers near the sea. Saltwater can make metal covers rust. The composite covers did not rust. The drains stayed clear and the covers stayed strong. The company shared what happened on the company overview page. Another city used smart manhole covers with sensors. These covers sent alerts if someone opened them. The city stopped stealing and kept the drains safe. You can read more about these ideas on the ductile iron manhole covers page.

Cities that use strong, rust-proof manhole covers keep their drains working and protect their city.

Manhole covers are important in every city. They keep people, cars, and workers safe. Manhole covers help drains work well. They help stop accidents from happening. Strong materials make manhole covers last longer. Cities need to check manhole covers often. Manhole covers must follow safety rules. They help keep water clean in the city. Manhole covers help save money on repairs. They stop people from stealing or breaking them. Manhole covers can hold heavy things like trucks. They help cities get bigger and better. Manhole covers work in rain, snow, and heat. Some manhole covers use smart technology. They help protect nature and the environment. Manhole covers make streets safer for everyone. They help workers do their jobs safely. Manhole covers help keep people healthy. Everyone needs manhole covers to stay safe. Safety in cities begins with manhole covers.

Find out more about manhole covers and city solutions at JSCA Composite.

Cities pick ductile iron, steel, or composite for manhole covers. Composite covers do not rust and are lighter. Ductile iron covers last longer on busy roads. You can read more about these materials at JSCA Composite.

Workers check manhole covers every few months. Busy places need more checks to stay safe. Inspections help find cracks, rust, or loose covers. Regular checks help keep streets safe. For more, visit the inspection manhole cover page.

Safety standards help stop accidents and keep people safe. These rules make sure covers hold enough weight and do not break. Cities use rules like EN 124 and AASHTO M306. You can read about these rules at the company overview.

Composite manhole covers do not rust and can be recycled. These covers help cities make less pollution and waste. Good covers keep drains clear and water safe. You can learn more at the water grate page.

People can find more about manhole covers and smart covers at JSCA Composite. The website has product details, rules, and a contact us page.