Views: 0 Author: Site Editor Publish Time: 2025-08-20 Origin: Site

Several main types of manhole cover gratings keep holes in roads safe. Each manhole cover grating has its own job. Some hold up heavy cars, while others let water drain away. Picking the right manhole cover gratings helps keep people safe and makes roads last longer. Studies show fiber-reinforced concrete makes these gratings stronger, able to hold up to 121% more weight and be 92% stiffer. The right thickness and material help manhole cover gratings last longer and prevent them from breaking.

Matching the manhole cover gratings to the job is very important. Good choices protect the manholes and keep people safe.

Manhole covers have different types like solid, grate, and recessed. Each type is made for a special use. They help keep people safe. They also protect things underground.

Materials like ductile iron, composite, concrete, plastic, and stainless steel are used. Each material has its own strength and benefits. The right material depends on where it will be used. It also depends on the conditions there.

Load classes like A15, B125, and D400 show weight limits. These classes help you pick the right cover. The cover must match the traffic and use in the area.

Round manhole covers are very common. They do not fall into the hole. They are easier to move. Square or rectangular covers need more care. This helps them stay safe.

Always match the manhole cover’s type, material, and load class to the place. Think about the traffic and environment. This keeps things safe and strong. It also makes maintenance easier.

Manhole covers have different types for different jobs. Each type works best in certain places. The EN-124 standard tells how to make and test these covers. This rule helps keep all manhole covers safe and strong.

Solid covers make a tough shield over manholes. They stop water, animals, and trash from getting inside. These covers also keep people from falling in. Workers use solid covers to reach pipes and cables underground. You can find these covers in factories, parks, airports, and building sites. They help control traffic, rainwater, and keep cities safe.

Note: Solid covers are often made from galvanized steel or ductile iron. These materials make the covers strong, not slippery, and easy to see.

Grate covers, also called gully grates or drain grates, let water pass through but block big trash. These covers help control water on the ground and stop floods. Grate covers are used near roads, highways, and parking lots. They help keep roads safe by stopping cars from sliding on water. Workers also use these covers to check and clean drains.

| Material | Typical Applications and Environments |

|---|---|

| Fiberglass | Used in factories, food plants, and boats; does not rust and is not slippery, good for wet places |

| Plastic | Used for walking paths, pools, dog areas, and gardens; cheap, not for heavy things |

| Cast Iron & Ductile Iron | Used for road drains, driveways, and factory drains; very strong, good for cars |

| Stainless Steel | Used where things must be clean, in factories, and for looks |

| Epoxy/Galvanized Steel | Used in factories, roads, driveways, and cable paths; very strong, does not rust |

Recessed covers look like the ground around them. Builders use them where there are paving stones or concrete layers. These covers can hold bricks or concrete, so they almost disappear. Recessed covers keep the area neat but still let people get to the manhole. Many have rough tops and locks to make them safer. They come in many strengths for different jobs.

Tip: Recessed covers are great for plazas, sidewalks, and places that need to look nice.

Manhole covers can be round, square, or rectangle. Most covers are round. This shape stops the cover from falling into the hole, even if turned. Workers can roll round covers, so they are easy to move. Square and rectangle covers are used in some places, but they can fall in if not careful.

Round covers stay safe and do not fall in.

Workers can roll round covers to move them.

Square and rectangle covers fit better in some spots but need care.

The type and shape of manhole covers depend on what they need to do. Some covers must hold up heavy cars, while others need to blend in. Picking the right cover keeps people safe and protects what is underground.

Manhole covers are made from different materials. Each material gives the cover special strengths. Some materials make covers safer and last longer. The material you pick changes how well the cover works. Covers are used in roads, parks, and sewers.

Ductile iron covers are used for tough jobs. This alloy is strong and does not rust easily. Ductile iron lasts longer than cast iron. Many covers have surfaces that stop slipping. Some have locks to keep them safe. Workers use load ratings to choose covers for busy places. Ductile iron does not need much care. Its structure and coating stop rust.

| Material | Key Properties and Advantages |

|---|---|

| Ductile Iron | High strength, corrosion resistance, lighter than cast iron, anti-skid, theft prevention, cost-effective |

| Cast Iron | Durable, heavy, less corrosion resistance |

Composite covers use resin and fiberglass. These covers are much lighter than cast iron. Workers can lift them easily. This lowers the chance of getting hurt. Composite covers resist chemicals and sunlight. They do not rust. They work well in drains, factories, and near the sea. Making and moving composite covers uses less energy. This helps the environment.

| Size (mm) | Grey Cast Iron (kg) | Ductile Cast Iron (kg) | Composite (kg) |

|---|---|---|---|

| 300 x 300 | 9.00 | 8.20 | 2.00 |

| 400 x 400 | 15.00 | 12.80 | 3.10 |

Tip: Composite covers save fuel and lower pollution when moved.

Concrete covers match sidewalks and plazas. These covers hold heavy things and look like the ground. Reinforced concrete covers work in busy places. They can break if hit hard. Workers use them where hits are not common.

Plastic and polymer covers are light and strong. They resist sunlight and chemicals. Polymer covers pass safety tests for weight and wear. They are safe for people and factories. FRP covers stop electricity from passing through. This helps in drains and sewers. Polymer covers cost less and work in quiet places.

Stainless steel covers are good for wet or clean places. These covers do not rust and are easy to wash. You see them in bathrooms, kitchens, and patios. They last a long time and look nice.

Stainless steel covers stop rust and handle chemicals.

They are clean and safe.

Workers use them outside and in businesses.

Aluminum covers are light and do not rust. They work well in wet or beach areas. Fiberglass covers are used in tough sea places. These covers are light and strong. They are safe and easy to care for. Fiberglass does not rot or grow mold. Their open design lets water drain and stops slips.

Fiberglass covers do not rot and handle water well.

They are easy to move and put in place.

These covers stop electricity and come in many styles.

Manhole cover gratings use many materials for different places. Picking the right cover keeps people safe. It also helps cities last longer.

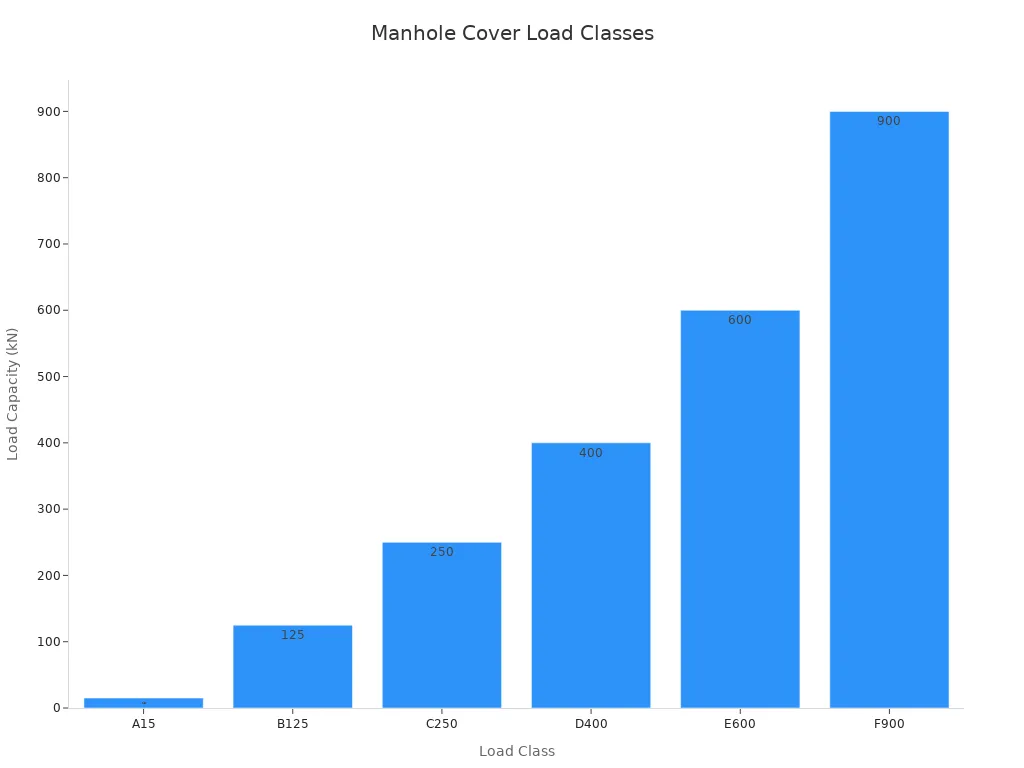

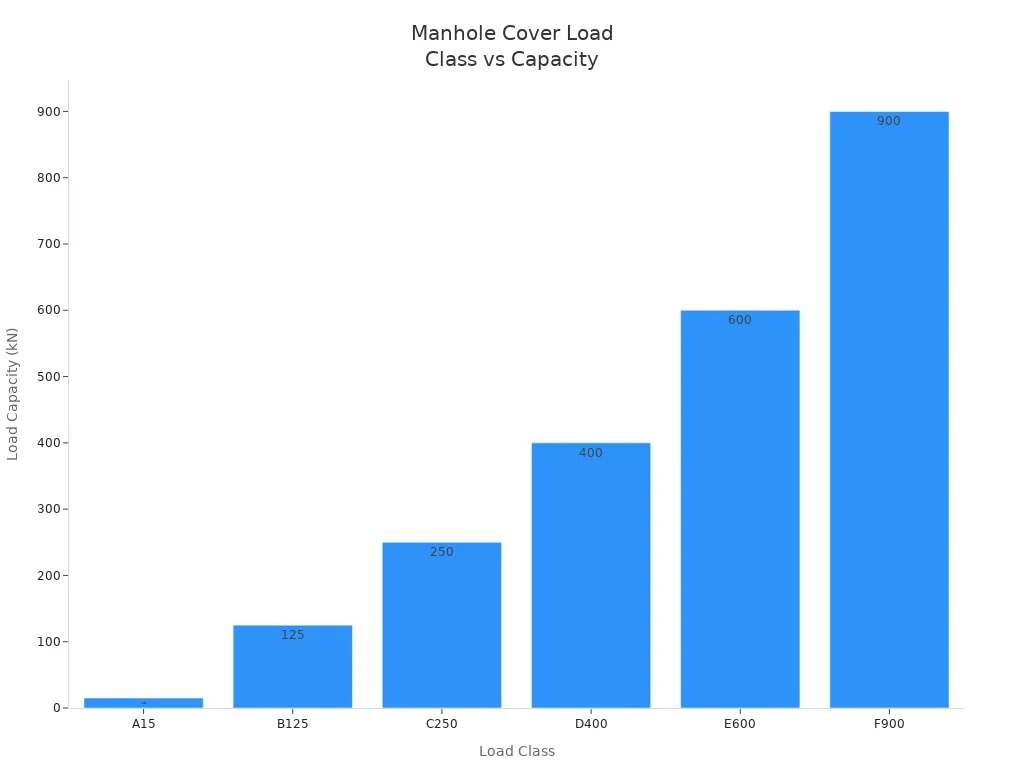

Manhole covers must handle different weights and traffic. The load classification of manhole covers helps builders and city planners pick the right covers for each place. This system uses classes like A15, B125, C250, D400, E600, and F900. Each class shows how much weight a cover can hold. Choosing the correct class keeps people and vehicles safe.

The load classification of manhole covers follows the BS EN 124 standard. This standard sets test loads for each class. The table below shows the main classes, their test loads, and where to use them:

| Load Class | Test Load (kN) | Approximate Load (tonnes) | Typical Application Areas |

|---|---|---|---|

| A15 | 15 | 1.5 | Pedestrian-only areas, gardens, sidewalks |

| B125 | 125 | 12.5 | Car parks, driveways, footpaths, shopping areas |

| C250 | 250 | 25 | Lightly trafficked roads, small car parks, kerbside |

| D400 | 400 | 40 | Roads, carriageways, parking areas, hard shoulders |

| E600 | 600 | 60 | Docks, loading bays, industrial sites, aircraft pavements |

| F900 | 900 | 90 | Airports, container terminals, heavy industrial zones |

Each load class matches the expected weight and traffic in its area. For example, A15 covers work best in places where only people walk. D400 covers are strong enough for busy roads with trucks and buses. F900 covers protect manholes in heavy load areas like airports.

The load classification of manhole covers links directly to where the covers will be used. Manhole covers in gardens or sidewalks need only light-duty covers. These covers are easy to move and resist rust. In car parks or driveways, B125 covers handle cars and small trucks. C250 covers fit small roads and parking lots with light traffic.

D400 covers serve main roads and busy streets. These covers must hold up under heavy vehicles. E600 and F900 covers are for the toughest jobs. Docks, loading bays, and airports need these covers to handle very heavy loads. The F900 class stands up to the weight of airplanes and large machines.

Tip: Always match the load classification of manhole covers to the real traffic and weight in the area. This keeps the manhole safe and the cover working for many years.

Picking the best manhole cover keeps people and things safe. You need to think about a few important things. The table below shows what to check when picking a manhole cover:

| Factor Category | Details and Considerations |

|---|---|

| Types | Round or square covers work in places like schools, airports, or highways. |

| Dimensions | Measure the hole size and frame depth to get a good fit. |

| Weight/Load Class | Pick the right load class for the traffic, from A15 for people to F900 for airports. |

| Material Properties | Choose materials like composite if you want covers that do not rust and are easy to move. |

| Installation & Safety | Look for covers with anti-theft parts and shockproofing to make them safer and easier to care for. |

| Standards & Certs | Make sure covers meet EN124 or ISO9000 rules for safety. |

| Environmental Factors | Think about traffic, safety, and where the cover will go, like in a city, home, or factory. |

The weather and place matter too. In factories or near the sea, ductile iron or fiberglass covers do not rust and can handle chemicals. Special coatings like galvanization or epoxy help covers last longer. Good drainage and tight covers stop water and trash from getting inside the manhole.

Manhole covers are used in many places in cities and for utilities. City roads use heavy cast iron covers to handle lots of cars and stop theft. In neighborhoods, ductile iron or pretty covers match bricks or stones. Pools need plastic, aluminum, or fiberglass covers because they do not rust and are safe for bare feet. City sewers and drains use strong covers to protect pipes and wires underground.

| Location Type | Common Materials | Key Properties and Reasons for Selection |

|---|---|---|

| Urban Roads | Cast Iron | Strong, lasts long, does not shake loose, and forms a protective layer. |

| Residential Areas | Ductile or Cast Iron | Looks nice, does not break easily, and matches the area. |

| Swimming Pools | Plastic, Aluminum, Fiberglass | Light, does not rust, and safe for feet. |

Security features keep manhole covers safe from being stolen or opened by people who should not. Locks, bolts, and special screws protect city and utility covers. Checking and cleaning covers often helps them last longer. Covers that do not slip and seal well stop accidents and wear. Composite covers keep water out and need less care, so they are good for busy city streets.

Tip: Always pick the right load class and material for the place and how it will be used. This keeps people safe and makes the cover last longer for all types of manholes and uses.

Knowing about the types, materials, and load classes of manhole covers helps stop accidents. It also keeps public places safe for everyone. Using the right covers for each manhole protects things underground. It also makes sure safety rules are followed. Cities and owners must follow rules when putting in covers. They also need to check them often.

Checklist for choosing manhole covers:

Choose covers that fit the place, traffic, and weather

Measure the manhole opening so the cover fits well

Pick materials that do not rust and fit the job

Use the right load class for the weight needed

Add anti-slip tops and locks to make covers safer

Plan to check and care for covers often

A manhole cover grating lets water go into the sewer. It stops big trash from getting in. It covers open manholes to keep people and cars safe.

Workers think about where the cover will go. They check how much weight it must hold. They look at the weather and what is around. Ductile iron is good for busy roads. Composite or fiberglass is better near water or chemicals.

Round covers do not fall into the hole. Workers can roll them to move them. The round shape spreads weight and makes the cover strong.

Yes, many covers have locks or bolts to stop theft. Some are made from heavy materials. Composite covers are not worth money, so thieves leave them alone.

City workers check manhole covers many times each year. They look for broken or loose covers. They also check if any covers are missing. Checking often helps stop accidents and keeps people safe.