Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Choosing the right manhole cover keeps people and things safe. A manhole cover grating with the right load rating makes roads and sidewalks safer. The material and size help the manhole cover last longer and fit well. Safety features and following rules are important for every project. This guide helps you know what to look for when picking a manhole cover grating.

Pick manhole covers by looking at where they go. Think about what kind of traffic will be there. Check the environment to make sure it is safe and strong.

Match the cover material to what your project needs. Use cast iron, ductile iron, FRP, or composite. Think about how strong it needs to be. Make sure it does not rust. Check if it is heavy or light.

Choose the right load rating class for the traffic. This helps stop accidents or damage.

Measure the manhole opening and frame very carefully. Pick the size and shape that fits well and stays secure.

Use anti-slip surfaces to help people stay safe. Add locking features to stop theft.

Follow local codes and rules for accessibility. This keeps your project legal and safe for everyone.

Check, clean, and take care of covers often. This helps them last longer and stops dangers.

Think about using new manufacturing methods like CNC. This can make covers better, safer, and faster to produce.

Cities need strong manhole cover grating. Streets and sidewalks get used a lot. Heavy cars and trucks drive over them every day. Engineers pick covers that can handle people and cars. Hinges and locks help stop people from stealing covers. Anti-slip surfaces keep people from slipping in busy places. Some covers have special logos or designs to match the area. Round covers are common in cities. They do not shift easily and are simple to move for repairs.

Tip: In cities, airtight and watertight seals on manhole covers stop bad smells and water leaks. This is very important for homes and apartments.

Rural areas have different needs for manhole cover grating. There is less traffic, but farm vehicles can be heavy. Budgets are smaller, so medium-duty covers are used more. Rural covers may not need many security features. They still must last a long time. People choose round or square covers based on the road and how easy they are to fix. Sometimes, recessed covers look better in nature.

Some places have chemicals that touch manhole cover grating. This happens in factories or water treatment plants. Covers must resist corrosion in these places. Ductile iron is a good choice because it does not get damaged by chemicals. It also bends without breaking. Special coatings like galvanization or epoxy protect the cover from harsh chemicals. Engineers pick covers that fit tightly. This stops chemicals from getting under the cover and causing rust.

Corrosion resistance keeps the cover safe from chemicals.

Epoxy and galvanization make the cover last longer.

Tight covers stop chemicals from getting inside.

Wet places, like near the ocean or where it rains a lot, need special care. Manhole cover grating here must not rust or get water damage. Bituminous coatings keep water out and help the cover last. Drainage holes let water flow out, so it does not pool and cause rust. Good airflow under the cover keeps moisture from building up. The right material and design help the cover last longer, even when it is wet.

Places where people walk, like parks and office areas, need lighter manhole cover grating. Anti-slip designs help stop people from falling. These covers can bend a little to make walking comfortable. Some covers have logos or designs to show where they are or to look nice.

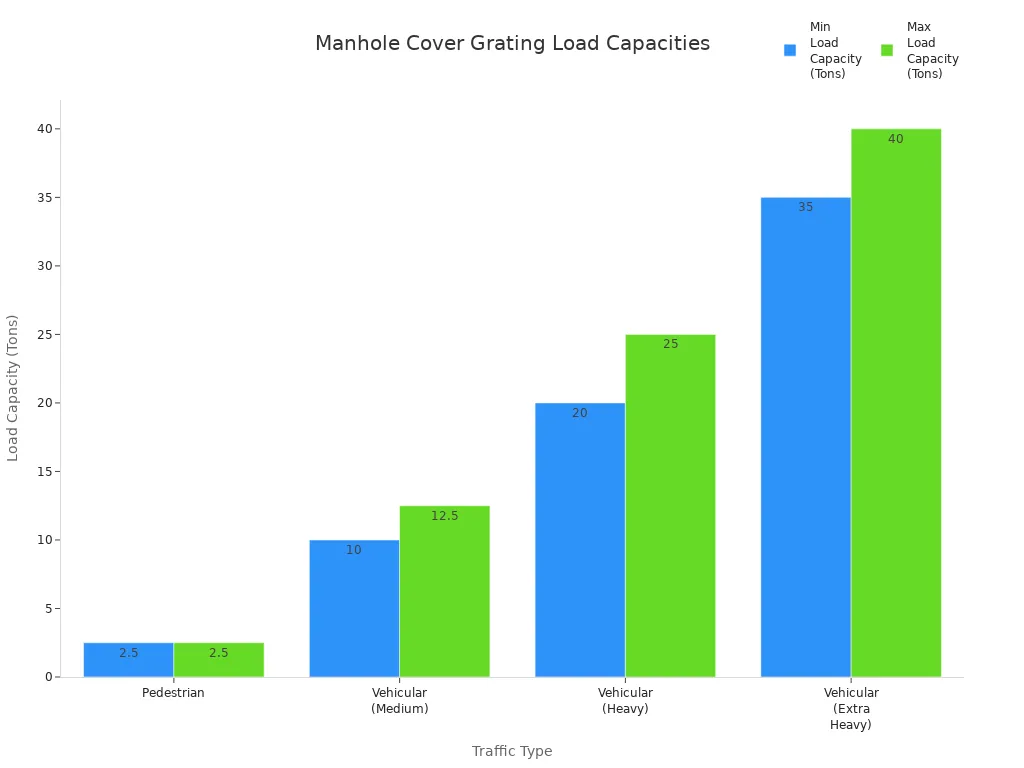

| Traffic Type | Load Capacity Range (Tons) | Typical Applications | Relevant Standards |

|---|---|---|---|

| Pedestrian | ~2.5 (Light Duty LD 2.5) | Footpaths, pathways, cycle tracks | IS:1726, BSEN-124 |

| Vehicular (Medium) | 10 - 12.5 | Roads with medium vehicular traffic | IS:1726, BSEN-124 |

| Vehicular (Heavy) | 20 - 25 | Heavier vehicular traffic | IS:1726, BSEN-124 |

| Vehicular (Extra Heavy) | 35 - 40 | High impact, heavy traffic areas | IS:1726, BSEN-124 |

Manhole cover grating for cars and trucks must be very strong. Roads and parking lots need covers that hold a lot of weight. Engineers use banding and welding to make covers stronger. Special finishes and serrations help stop slipping, even if the cover is wet or oily. Picking the right cover means it will not break when cars or machines drive over it.

Note: Using the right manhole cover grating for each type of traffic keeps people and cars safe. It also helps the cover last longer.

Rules help people pick the right manhole cover grating. Cities and towns must follow these rules to keep everyone safe. These rules come from both national and local codes. Codes tell us how strong and big the grating should be. They also say what safety features are needed. Engineers look at these codes before they choose a grating.

The table below lists some main codes and standards for manhole cover gratings:

| Regulatory Code / Standard | Key Requirements for Manhole Cover Grating Selection |

|---|---|

| Uniform Federal Accessibility Standards (UFAS) | Gratings in walking areas must have holes no bigger than 1/2 inch (13 mm) in one direction. If the holes are long, they must go across the path, not along it. This keeps wheelchair wheels from getting stuck. |

| Americans with Disabilities Act (ADA) Guidelines | Trench drain grates must have holes no bigger than 1/2 inch across the main path. The pavement around the grate must not be steeper than 1:48 (about 2%) so everyone can use it. |

| Architectural Barriers Act of 1968 | This law gave the power to make UFAS rules. Federal agencies use these rules to make public places easy to use. |

| ANSI A117.1 Standards | UFAS uses ANSI A117.1-1980 rules for barrier-free design. Many states and towns use these rules for their building codes. |

Tip: Always check your local building codes. Some cities have extra rules for manhole covers in busy or special places.

Accessibility rules help everyone use sidewalks and streets safely. People who use wheelchairs or walkers need smooth and safe paths. Manhole cover gratings must not make it hard or dangerous to cross.

The Americans with Disabilities Act (ADA) gives clear rules for grating design. The holes in the grating cannot be too wide. If the holes are long, they must go across the path, not along it. This stops wheels from getting stuck. The ground around the grating must stay almost flat. If it is too steep, it is hard for people to cross.

Here is a summary of ADA rules for manhole cover gratings:

| ADA Requirement | Description |

|---|---|

| Maximum Opening Size | Holes in trench drain grates must not be bigger than 1/2 inch across the path. This keeps wheelchair wheels from getting stuck. |

| Orientation of Openings | Holes should go across the main path to keep it easy to use. |

| Pavement Slope | The ground around the grate must not be steeper than 1:48 (about 2%). The best slope is 3/16 inch per foot to stay safe even if the ground is not perfect. |

Note: Following accessibility rules is not just about the law. It helps everyone move safely, like kids, older people, and people with disabilities.

Engineers and builders must match manhole cover grating features to these codes and standards. This keeps the project legal and safe for all people.

Cast iron manhole cover is still a top pick for many jobs. This material is very strong and holds heavy things. Engineers use cast iron manhole cover where cars, trucks, or buses go. Cast iron manhole cover is strong because it is packed tightly. It does not bend when something heavy is on it. Many cities use cast iron manhole cover on busy roads. These covers can hold thousands of pounds and do not break.

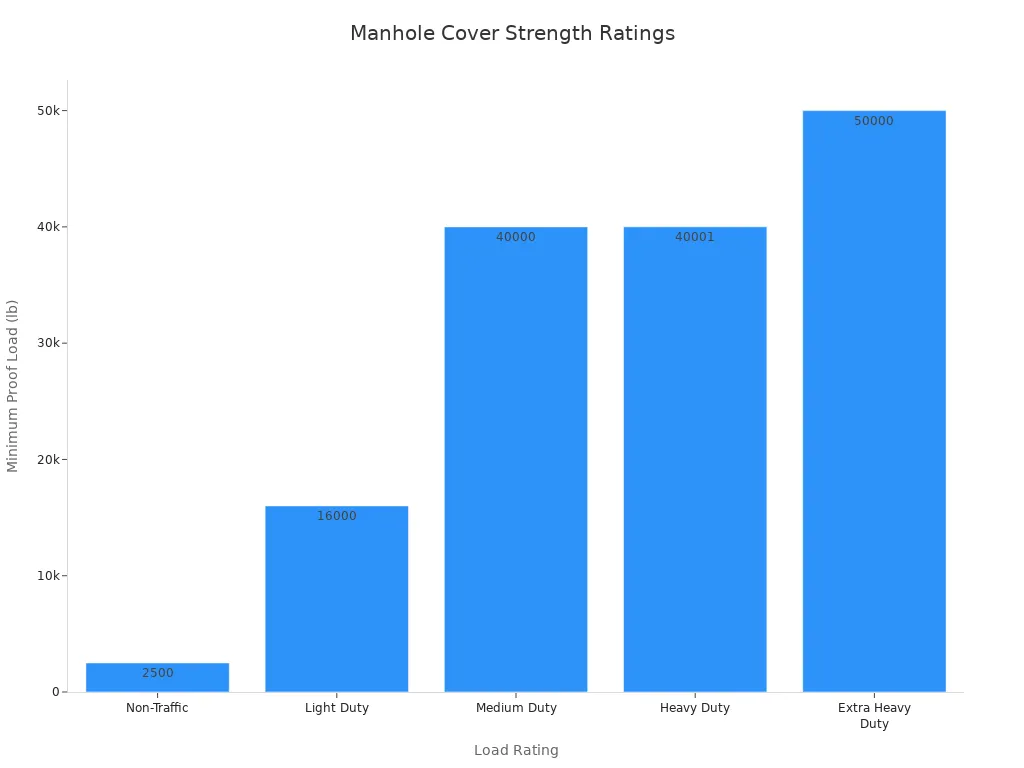

Cast iron manhole cover comes in different strengths. Light duty covers are good for places where people walk. Medium duty covers work for small streets. Heavy and extra heavy duty covers are for highways and factories. The chart below shows how much weight each type can hold.

Cast iron manhole cover lasts a long time if you take care of it. This material can stay strong for many years. Cast iron manhole cover does not get hurt by weather or cars. If it has a coating, it can even handle chemicals. Engineers like cast iron manhole cover because it is tough and lasts long. Heavy duty cast iron manhole cover can take a lot of use and bad weather.

Cast iron manhole cover needs to be checked and cleaned often. If it does not have a coating, it can rust. Many covers get a special layer to stop rust. Cast iron manhole cover is heavy, so it is hard to steal but also hard to put in place. The table below shows how cast iron manhole cover is different from other types.

| Feature | Cast Iron Manhole Covers | FRP (Composite) Manhole Covers |

|---|---|---|

| Weight | Heavy, difficult to install and maintain | Lightweight, easy to handle and install |

| Theft Risk | High, due to scrap value | Low, not recyclable and less attractive to thieves |

| Corrosion Resistance | Requires coatings or treatments | Naturally corrosion-resistant |

| Maintenance | Requires regular maintenance | Low maintenance |

| Cost | Generally less expensive initially | Higher initial cost but cost-effective long-term |

| Safety | Risk of electric shock | No electric shock risk |

| Customization | Limited shapes and sizes | Can be customized in shape and size |

| Anti-slip Properties | Standard | Has anti-slip properties |

FRP manhole cover means Fiber Reinforced Polymer. FRP manhole covers are made from fiberglass, resin, and plastic. These materials make FRP manhole covers very good at fighting rust. FRP manhole covers do not rust or rot, even in wet or chemical places. Engineers use FRP manhole covers in water plants, chemical factories, and near the sea. FRP manhole covers have a special layer that keeps out water and chemicals. FRP manhole covers do not need much care and keep looking new for a long time.

The table below shows how FRP manhole covers do better than old materials at fighting rust and lasting long.

| Property | FRP Manhole Covers | Traditional Materials (Steel, Concrete, Wood) |

|---|---|---|

| Corrosion | Highly resistant, especially in seawater and chemical environments | Prone to corrosion, rust, cracking, and degradation |

| Maintenance | Minimal maintenance; no painting or surface treatment needed | Requires frequent maintenance, painting, and treatments |

| Durability | Excellent resistance to decay, rust, and pests | Susceptible to corrosion, cracking, and decay |

FRP manhole covers also do not shake much and do not change size with heat. These things make FRP manhole covers great for places with lots of movement or changing weather.

Slip resistance is very important for frp manhole covers. FRP manhole covers have rough tops to help stop slips and falls. Engineers use FRP manhole covers in parks, sidewalks, and busy paths. FRP manhole covers can have special coatings and designs for more grip. FRP manhole covers can be made in any shape and can have logos or patterns.

FRP manhole covers are light, so they are easy to move and put in. FRP manhole covers are not worth much to thieves, so they are not stolen often. FRP manhole covers do not carry electricity, so they are safe near wires. Here are the main things about frp manhole covers:

Light and easy to move

Strong and lasts long

Can be made stronger in certain ways

Does not change size much with heat

Handles shaking well

Fights rust and rot

Not likely to be stolen

Can be made in many shapes and sizes

Has a rough top for safety

Engineers pick FRP manhole covers because they last long and save money. FRP manhole covers help lower repair costs and make places safer.

Ductile iron manhole covers are heavier than FRP manhole covers. This extra weight helps ductile iron covers stay in place on busy roads. Ductile iron manhole covers do not bend or crack as easily as cast iron manhole cover. Cast iron manhole cover is lighter, but ductile iron manhole covers are stronger and bend more before breaking. Some ductile iron manhole covers can weigh up to 90 tonnes for special jobs. FRP manhole covers are much lighter and easier to put in.

Ductile iron manhole covers last a long time on busy roads. Ductile iron manhole covers last longer than cast iron manhole cover. Engineers use ductile iron manhole covers where there is lots of traffic and bad weather. Ductile iron manhole covers do not rust easily and do not need much care. Many ductile iron manhole covers last for many years with little work. FRP manhole covers also last long in places with lots of chemicals, but ductile iron manhole covers can hold more weight.

The table below shows which manhole cover materials are used most and what they are good for.

| Material | Key Attributes and Usage | Market Share Position |

|---|---|---|

| Stainless Steel | Exceptional durability, corrosion resistance, high strength-to-weight ratio. Widely used in hygiene-sensitive areas. | Largest market share |

| Ductile Iron | Strong, impact resistant, withstands heavy loads. Increasingly preferred over cast iron. | Second largest |

| Composite Materials | Lightweight, corrosion resistant, non-conductive, environmentally friendly, gaining traction. | Growing market share |

| Plastic | Cost-effective, lightweight, used in residential and light-duty applications. | Niche applications |

| Aluminum | Lightweight, easy to handle, suitable for frequent access areas. | Niche applications |

| Cast Iron | Historically widely used due to cost-effectiveness and robustness but being replaced by ductile iron and composites. | Declining |

| Steel | Widely used in industrial and commercial applications for strength and durability. | Significant but less than stainless steel and ductile iron |

Ductile iron manhole covers are strong, heavy, and last a long time. FRP manhole covers are great for places that need rust protection and slip safety.

Composite manhole covers help protect the environment. They use resin and fiber instead of heavy metals. This saves natural resources and means less iron ore is needed. Making composite covers uses less energy than making cast iron manhole cover. Factories often use recycled fibers or synthetic resins. This helps keep the earth cleaner.

Composite covers are much lighter than metal covers. Lighter covers mean trucks use less fuel to deliver them. This helps lower greenhouse gas emissions. It also helps fight climate change. Composite covers last a long time, so they do not need to be replaced often. This means less waste goes to landfills. Many composite covers can be recycled when they are old. This helps support a circular economy.

Composite covers do not rust or break down like metal covers. This keeps streets and sidewalks safer for people and animals. The smooth surface does not hurt wildlife. These covers also absorb vibrations, so they make less noise than metal covers.

Composite manhole covers are a greener and better choice for cities today.

Here are some environmental benefits of composite manhole covers:

Use fewer natural resources by using resin and fibers.

Need less energy to make, so carbon footprints are lower.

Lighter weight means less fuel and fewer emissions during transport.

Last longer and need fewer replacements, so there is less waste.

Can be recycled, which helps the circular economy.

Resist corrosion, so streets are safer and wildlife is protected.

Absorb vibrations and make less noise.

Composite manhole covers work well in many places. Cities use them on sidewalks, parks, and bike paths. They are light, so workers can move them easily. Workers do not need special machines to lift them. This saves time and money.

Engineers pick composite covers for places with lots of rain or chemicals. These covers do not rust, so they last longer in wet or harsh places. Schools, hospitals, and shopping centers use composite covers because they are safe and easy to use. The features of frp manhole covers, like slip resistance and non-conductivity, make them a good choice where safety is important.

Many companies use frp manhole covers in water plants and chemical factories. These covers can handle strong chemicals and do not break down. The features of frp manhole covers also include custom shapes and colors. Cities can add logos or patterns to match the area.

The table below shows where frp manhole covers are used and their main features:

| Application Area | Main Features of FRP Manhole Covers |

|---|---|

| Sidewalks & Parks | Lightweight, slip-resistant, easy to install |

| Industrial Facilities | Corrosion-resistant, chemical-proof |

| Schools & Hospitals | Non-conductive, safe for public use |

| Roads & Parking Lots | Durable, strong, customizable |

| Water Treatment Plants | Long-lasting, resists harsh chemicals |

The features of frp manhole covers help cities and companies save money on repairs. These covers also help protect the environment and keep people safe. When compared to a cast iron manhole cover, frp manhole covers give more benefits for modern projects.

To pick the right manhole cover grating, you need to know about load ratings. Each cover must hold up the weight and pressure from where it is used. Engineers use load rating classes to match covers to the right spot. These classes help people know if a cover is safe for people, cars, or even airplanes.

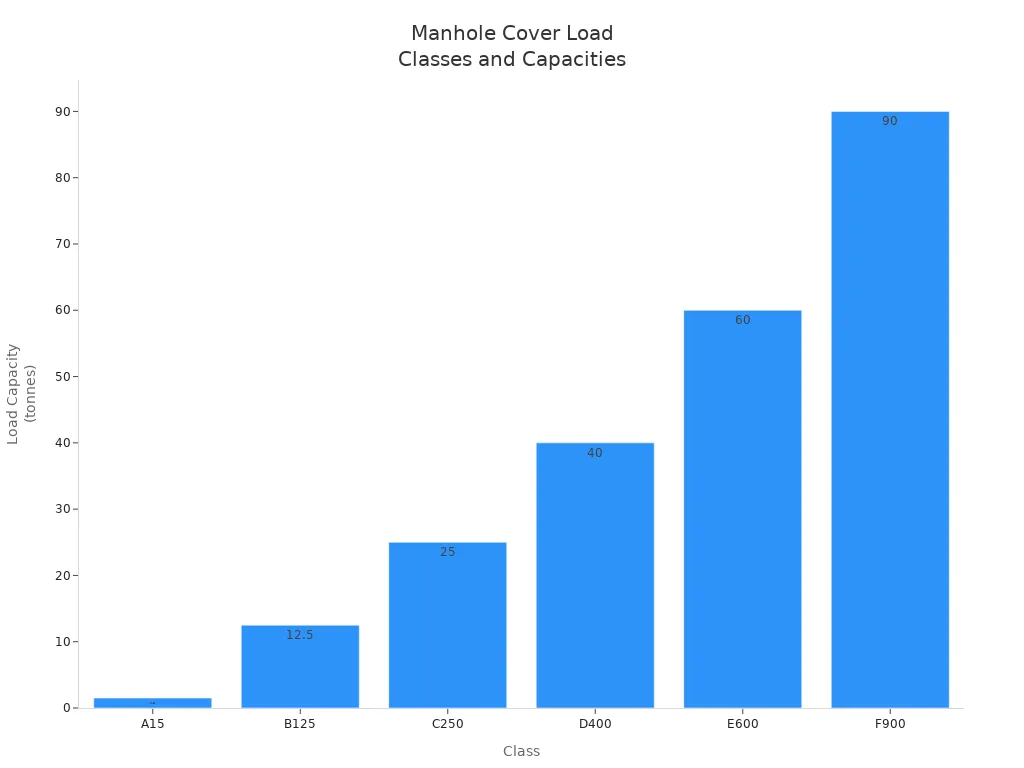

Manhole cover gratings have different loading classes. Each class shows how much weight the cover can take. The most common guide is the product standard en 124. The table below lists the main classes, their load limits, and where to use them:

| Class | Load Capacity (tonnes) | Typical Installation Environment |

|---|---|---|

| A15 | 1.5 | Pedestrian and cyclist-only areas |

| B125 | 12.5 | Footways, pedestrian areas, car parks |

| C250 | 25 | Near kerbside channels, limited carriageway extension |

| D400 | 40 | Carriageways, hard shoulders, pedestrian streets |

| E600 | 60 | Loading areas, docks, heavy wheel loads |

| F900 | 90 | Aircraft pavements, very heavy wheel loads |

A15 covers can hold up to 1.5 tonnes. These covers are best for places where only people or bikes go. You see A15 covers in parks, sidewalks, and gardens. They are not made for cars or trucks.

B125 covers can hold 12.5 tonnes. These covers work well in footways, places where people walk, and car parks. Sometimes small cars may drive over them, but they are not for busy roads.

C250 covers can take up to 25 tonnes. Engineers use these covers near kerbside channels and where light vehicles might go. These covers are good for slow traffic areas.

D400 covers are heavy duty. They can hold 40 tonnes. These covers are used on roads, hard shoulders, and busy streets. Trucks and buses can drive over D400 covers safely.

Tip: Always pick the right loading class for the traffic. If you use the wrong class, it can break or cause accidents.

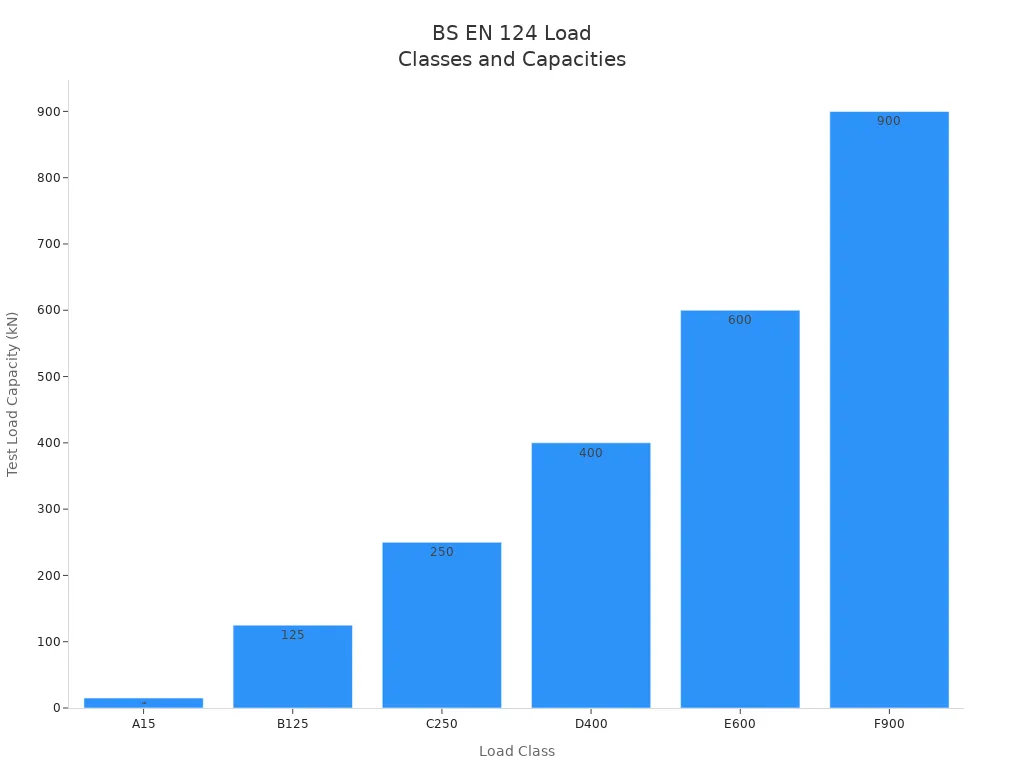

International standards help engineers pick the right manhole cover grating. EN 124 is the most used standard. This standard sets the rules for load rating and loading class. The table below shows how EN 124 groups each class by test load and where to use them:

| BS EN 124 Load Class | Test Load Capacity | Typical Installation Area / Group |

|---|---|---|

| A15 | 15 kN (1.5 tonnes) | Pedestrian areas only (Group 1) |

| B125 | 125 kN (12.5 tonnes) | Car parks, pedestrian areas with occasional vehicle access (Group 2) |

| C250 | 250 kN (25 tonnes) | Slow moving traffic areas, kerbside channels (Group 3) |

| D400 | 400 kN (40 tonnes) | Carriageways, hard shoulders, parking areas (Group 4) |

| E600 | 600 kN (60 tonnes) | High wheel load areas like docks, aircraft pavements (Group 5) |

| F900 | 900 kN (90 tonnes) | Extremely high wheel load areas such as airports (Group 6) |

EN 124 is the main standard in Europe and many other places. Some projects use ASTM standards, but EN 124 is most common for load rating. These standards make sure every cover is safe.

Testing checks if each manhole cover grating meets its load rating. Makers test covers by putting weight on them until they reach the right class. Certification proves the cover passed these tests.

Certified covers have a label or mark. This mark shows the cover meets the loading class and load limit. Engineers look for this mark before using a cover. Certification helps people trust the cover will not break.

Compliance means the cover follows all rules and standards. Engineers check compliance before putting in a cover. They look at the loading class, load rating, and test results. Only covers that follow the rules go into public roads, sidewalks, and airports.

Note: Always pick a manhole cover grating with the right certification and compliance. This keeps people and cars safe in all situations.

Measuring the diameter is the first thing to do. The clear opening diameter shows how wide the hole is. Workers use strong tape measures or rods to check this. Guessing or using old records can cause mistakes. Many people pick the wrong size because they do not measure well. Trash or bars in the way can also make errors happen.

To stop these problems:

Use good tools like tape measures and rods.

Take out any trash before you measure.

Measure the clear opening, not just the cover.

Check your measurements twice and write them down.

Getting the diameter right keeps the cover safe. It also stops leaks and accidents.

Manhole covers come in different shapes. The most common are round, square, and rectangular. Round covers work best in city streets. They do not shift or fall in. Square and rectangular covers are good for special jobs. The shape must match the frame and the hole. For square or rectangular covers, measure both length and width.

Tip: Always look at the frame’s shape before you order a new cover.

The frame holds the manhole cover in place. It must match the cover’s size and shape. If the frame is bent or broken, the cover will not fit. Not checking the frame can make things unsafe. Workers should look for cracks or rust before putting in a new cover. A flat and packed surface helps the cover sit tight.

Easy access is needed for fixing things. Covers should lift out without getting stuck. If the cover is too tight or the frame is not flat, it is hard to open. Using a water pass tool helps keep the cover level with the road. This makes the cover easy to remove and safe for everyone.

Most manhole covers come in standard sizes. Round covers are usually 5 to 60 inches wide. Square covers are often 8 to 60 inches wide. Many cities use 24-inch covers for roads and sidewalks. Standard sizes help you find a quick replacement. Traffic-rated covers like H-20 are for heavy loads. ADA styles and bolted grates can be ordered for special needs.

Some projects need custom sizes. Custom covers fit special shapes or frames. Factories can make rectangular or trench covers for special jobs. Custom covers can have company logos or extra strength. Engineers can ask for special products with drawings. Custom sizes help when standard covers do not fit.

Note: Always ask an expert and check all measurements before buying a new manhole cover. Getting the size right saves time, money, and keeps people safe.

Slip resistance is very important for manhole cover gratings. Busy sidewalks need covers that help stop slips and falls. SafTrax coatings make the surface rough and strong. These coatings last about ten years and work well on metal covers. They do not get damaged by oil or fuel. The grip is very good, even if the cover is wet or oily. This helps keep people safe in cities and on busy paths.

Other ways to stop slipping are raised chequer patterns and special anti-slip coatings. Raised patterns help shoes grip better. High-friction coatings meet safety rules like the UK HSE’s Pendulum Test Value of 36. The table below shows how different slip treatments work:

| Treatment Type | Description | Performance/Value | Pedestrian Suitability |

|---|---|---|---|

| SafTrax Non-Skid Coating | Durable, high-friction, resists oils and corrosion | 1:1 friction, 10-year life | Excellent |

| Modified Raised Chequer Profile | Raised pattern for extra grip | >70 PSRV | Good with modifications |

| High-Friction Anti-Slip Coating | Applied coating for extra slip resistance | Meets PTV 36+ | Very effective |

The right surface treatment keeps people from slipping and getting hurt. Anti-slip coatings and rough textures help stop falls. City planners pick covers with these features for parks, crosswalks, and plazas. These covers are safer in rain or ice. Cleaning and checking the covers often keeps them safe for everyone.

Security features help stop people from stealing or messing with manhole covers. In risky places, covers use bolts or hinges with special keys. When installed right, the covers stay locked and safe. Some covers have unique keys for more control. Vault D400 covers use strong locks made of stainless steel.

Hinged covers with one lock are easy to open.

Captive hinges make lifting simple and lower theft risk.

Safety-stop hinges keep covers from closing by mistake.

Safety keyways stop keys from slipping out.

Taking care of locks keeps covers safe over time. Workers should check and tighten locks often, especially where theft happens a lot. Using standard lifting keys, like BS7903, makes opening covers safe and easy. Regular care helps the locks work well and keeps the area safe.

Odor control is important in places like landfills and sewers. Polyethylene films are used as barriers under covers. These films block rain and keep bad smells inside. They work better than soil and help keep the air clean.

Places like hospitals and schools need extra sealing to work better. Hybrid covers use check valves and carbon filters for both air flow and odor control. These covers have vent holes and filters to let gases out safely. UV-resistant finishes and modular designs help covers last longer and make repairs easier. Standards like EN 124 and BS EN 476 support these features and help protect people and the environment.

Tip: Vented covers help stop gas from building up and causing explosions. This is very important in wet or coastal places. Some vented covers can connect to sensors to watch for problems in real time.

Lifter dollies help workers move heavy manhole cover gratings safely. These tools have wheels and levers to lift covers easily. Workers use lifter dollies to avoid hurting their backs or muscles. Many lifter dollies have arms that can change size for different covers. Some lifter dollies use magnets or hooks to hold the cover tight. One person can often move a heavy cover with a lifter dolly.

Lifter dollies work in busy streets, parks, and factories. Workers roll the dolly to the cover and attach the lifting arm. Then they lift the cover up smoothly. This keeps the cover steady and stops it from falling. Some lifter dollies fold up so they fit in a truck or workshop. Using a lifter dolly also helps stop damage to the cover and the ground.

Tip: Always look at the lifter dolly’s weight limit before using it. The right tool helps keep everyone safe.

Good handling tools make lifting and moving manhole covers safer. Workers use special hooks, bars, and attachments for this job. These tools help workers avoid hurting their fingers or hands. The table below shows some common tools for handling manhole covers:

| Tool Name | Description |

|---|---|

| 27" Hand Hole Hook | T-handle tool made of coated steel with angled shaft for easy insertion into hand hole lids. |

| Lansing Forge Manhole Cover Hook | Fits under pry points for lifting; small and easy to carry. |

| Easy Off Manhole Cover Remover | Light, strong tool made from thick steel tubing for tough covers. |

| Hubbell Quazite 27" Long Cover Hook | Steel hook, 27 inches long, used for lifting covers. |

| Condux Hand Hole Hook | Makes unlocking and lifting covers easier, about 26 3/4" long. |

Some jobs use special accessories to make work safer and faster. Grate attachments help machines lift big stormwater gates and electric vault grates. Swing arm attachments let workers move covers away from the hole and put them back without leaving their truck. Folding swing arm attachments can go on the front or back of a truck for more choices. Camera monitors let workers see the cover from inside the truck, so they can remove and replace covers from far away.

| Accessory Name | Description |

|---|---|

| Grate Attachment | Lets machines lift stormwater gates and big electric vault grates. |

| Swing Arm Attachment | Helps workers swing the cover away and put it back safely. |

| Folding Swing Arm Attachment | Can go on the front or back of a truck for flexible use. |

| Camera Monitor Option | A color screen inside the truck to help with remote cover removal and replacement. |

Using the right tools and accessories keeps workers safe and stops damage to manhole covers. Training and checking tools often also help keep the job safe.

Getting the surface ready is important for a safe manhole cover grating. Workers pick the right cover by checking size, weight, and weather needs. They gather tools like a tape measure, level, shovel, and concrete or asphalt mix. First, they measure the manhole opening with a tape measure. They mark the spot so the cover goes in the right place.

A strong and flat base is needed. Workers put bricks around the hole and pour concrete or asphalt. This base holds the frame and keeps it from moving. The frame must be even with the ground. A level helps check if it is flat. More concrete is poured around the frame to make it even with the top. This stops water from sitting on the cover and keeps it steady.

Safety is always important when installing a manhole cover grating. Workers wear gloves, boots, and eye protection. They keep the area clean so no one trips or falls. Heavy covers need good lifting or special tools like lifter dollies. This helps stop injuries. The contractor checks all tools before work starts. Workers talk to each other to stay safe, especially when moving heavy covers.

Workers put the frame into the hole they made. They make sure the frame is flat and does not lean. They use a level to check every side. The frame must fit tight on the base. Workers pour more concrete around the frame to hold it in place. They smooth the top so it looks nice.

When the frame is set, workers put the manhole cover on top. They check that it is flat and does not lean. If needed, they use screws or bolts to lock the cover. Tight screws stop the cover from moving or being stolen. Workers fill any spaces with concrete or asphalt. They test the cover to make sure it holds weight and does not move.

Checking the cover often is a big part of maintenance. Workers look for cracks, chips, or other damage. They check if the cover is flat and does not move. Inspections help find problems early. This saves money and keeps people safe.

Cleaning the manhole cover grating helps it last longer. Workers take away dirt, trash, and things that can cause rust. They make sure water can drain away from the cover. Teaching workers and the public to report damage helps repairs happen fast.

Tip: Spread weight across the cover to help it last longer and not break early.

Manhole cover gratings are made in two main ways. These are CNC and manual methods. Each way changes how the final product turns out. The method you pick affects quality, speed, and safety.

CNC uses machines and computers to make manhole cover gratings. Workers tell the machines the right size and shape. The machines cut, drill, and finish the covers very carefully. Robotic arms put down fibers and mix resins by themselves. This makes sure every cover is the same.

CNC machines work quickly. They can make lots of covers fast. The machines help keep workers safe. Workers do not have to touch chemicals or use heavy tools as much. The machines do most of the hard jobs. This means fewer accidents and health problems.

CNC makes covers that are always the same. Each cover meets strict rules like EN 124:2015. Machines check for mistakes early. Factories can make more covers with fewer errors. One example showed a big jump in how many covers were made. Downtime dropped a lot. Product quality got better and more covers met the rules.

Manual manufacturing needs skilled workers. They put fibers down by hand and mix resins themselves. Workers use hand tools to trim and finish each cover. This takes more time and depends on how good the worker is.

Manual ways can cause more mistakes. Covers might have air bubbles or be too thick or thin. These problems can make covers weaker. Workers also face more danger. They touch chemicals and tools directly. This can hurt their health or cause injuries.

Manual production is slower than CNC. It is hard to make many covers fast. Making each cover the same is tough. Some covers may not meet all the rules. Factories might have to fix or throw away some covers.

The table below shows how manual and CNC manufacturing are different for manhole cover gratings:

| Aspect | Manual Manufacturing Process | CNC / Automated Manufacturing Process |

|---|---|---|

| Process Steps | Hand lay-up of fibers, manual resin mixing and application, manual curing, manual trimming and finishing | Robotic fiber laying, automated resin mixing and dosing, CNC trimming, milling, drilling, and finishing |

| Quality Consistency | Highly dependent on operator skill; prone to defects like air bubbles, dry spots, uneven thickness, delamination | Precise control over fiber placement and resin dosing; consistent layering and curing; minimal human error |

| Production Speed | Slower due to labor-intensive hand lay-up and curing times | Faster throughput with continuous robotic operation and CNC finishing stations |

| Safety | Exposure to hazardous chemicals (resins, catalysts); ergonomic strain from manual labor | Reduced chemical exposure via automated handling; less manual grinding and tool use; improved workplace safety |

| Repeatability & Scalability | Difficult to maintain consistent mechanical properties and dimensional accuracy; limited scalability | High repeatability with CAD/CAM integration; scalable production lines adaptable to different designs and volumes |

| Compliance with Standards | Variable compliance due to quality inconsistencies | High compliance with standards like EN 124:2015 ensured by precise process control and automated quality inspections |

| Defect Rates | Higher scrap and rework due to human error and variability | Lower scrap rates and rework due to controlled processes and real-time monitoring |

| Case Study Outcome | N/A | 71% increase in production output; 40% reduction in labor; 80% reduction in downtime; product quality variation reduced from ±12% to ±3%; compliance improved from 87% to 99.8% |

Tip: CNC manufacturing gives better quality, safety, and speed for manhole cover gratings. Manual ways may work for small or special jobs, but CNC is best for big projects.

Manhole covers come in different types for many uses. Each type is made for cities, factories, or homes. Knowing the types helps people pick the right one. This keeps everyone safe and makes sure water drains well.

Solid covers are flat and closed on top. They stop water, dirt, and smells from getting in or out. These covers are good where you do not want water or trash inside. City streets, airports, and factories use solid covers a lot. Heavy-duty solid covers, like cast iron or ductile iron, can hold cars and trucks. Their heavy weight keeps them from moving or being stolen.

A sealed surface means the cover fits tight on its frame. This stops rain and bad smells from leaking out. Sealed covers are used near hospitals or food markets. Some have special coatings to stop rust or damage from chemicals. Others have rough tops to help people not slip.

Gratings look different because they have open spaces. The bars let water and air move through. Gratings help drain water and let air flow in busy places.

Drainage gratings let rainwater go into the ground. Water goes through the holes and into pipes below. This keeps roads dry and safe. Gratings must be strong for cars but open for water to pass.

Some gratings let air move in and out of underground spaces. Good airflow stops gas from building up. This keeps workers safe. You see these gratings in tunnels, basements, and utility rooms.

Access covers let workers get to pipes, wires, or other things below ground. These covers make it easy to check and fix problems. Access covers come in round, square, or rectangle shapes.

Solid covers, gratings, and access covers all do different jobs. Solid covers seal and protect. Gratings help with water and air. Access covers let workers go underground. Some covers, like recessed manhole covers, match the ground in parks or malls. Others, like inspection chamber covers, help workers reach sewer pipes. Picking the right cover depends on where it goes and what it needs to do.

Tip: Always use the right cover for the job. This keeps people safe and makes fixing things easier.

| Type | Main Function | Common Materials | Typical Locations |

|---|---|---|---|

| Solid Cover | Sealing, protection | Cast iron, ductile iron, steel | Roads, airports, factories |

| Grating | Drainage, ventilation | Steel, ductile iron, composite | Streets, parking lots, tunnels |

| Access Cover | Utility access | Cast iron, composite, steel | Sidewalks, utility vaults, gardens |

Gully grates help control water on roads and in public places. These covers sit on top of drains. They let water go into pipes but stop big trash from getting in. Engineers use gully grates to stop floods and keep roads safe when it rains a lot.

Common Applications of Gully Grates:

Roadways:

Cities put gully grates by the curb and in gutters. These grates catch rainwater from the street and send it to the stormwater system. This keeps water from making puddles that can cause crashes.

Parking Lots:

Big parking lots use gully grates to drain water fast. If there are no grates, water can build up and hurt the pavement or make slippery spots for cars and people.

Industrial Sites:

Factories and warehouses have gully grates near loading docks and yards. These grates take care of water from cleaning, spills, or rain. They help keep work areas dry and safe.

Parks and Playgrounds:

Parks use gully grates on paths and play spots. The grates stop grass and dirt from washing away when it storms.

Residential Areas:

Neighborhoods use small gully grates in driveways and gardens. These grates help keep homes safe from water by moving rain away from buildings.

Tip: Clean gully grates often to stop clogs. Leaves, trash, and dirt can block the holes and keep water from draining.

Types of Gully Grates by Application:

| Application Area | Typical Grate Material | Key Features |

|---|---|---|

| Urban Streets | Ductile Iron, Steel | High strength, anti-slip |

| Industrial Facilities | Composite, Steel | Corrosion resistance |

| Parks & Playgrounds | Composite, FRP | Lightweight, safe edges |

| Residential | Plastic, Composite | Easy to install, low theft risk |

Gully grates come in many shapes and sizes. Some have thin slots to keep bike tires and wheelchair wheels safe. Others have wide bars for heavy-duty places. Engineers pick the right grate for the traffic, water, and safety needs.

Key Benefits of Using Gully Grates:

Stop streets from flooding

Keep big trash out of pipes

Make roads and walkways safer

Lower repair costs by blocking large things

Gully grates help towns and cities handle water safely. Picking the right kind for each place keeps people, cars, and property safe during storms.

Every project starts with understanding its needs. The team should look at the location, traffic type, and environment. They must decide if the area has heavy vehicles, only pedestrians, or both. Some places need covers that resist chemicals or moisture. Others need covers that stop odors or fit special shapes. The team should also check if the project must follow local codes or accessibility rules.

Tip: Write down all project needs before choosing a manhole cover grating. This step helps avoid mistakes and keeps the project safe.

Choosing the right material is important for safety and durability. Cast iron works well for busy roads because it is strong. Ductile iron lasts longer and bends without breaking. FRP (Fiber Reinforced Polymer) resists rust and is light, so workers can move it easily. Composite covers help the environment and work in many places. The team should match the material to the site’s needs, such as weather, chemicals, or theft risk.

| Material Type | Best For | Key Benefit |

|---|---|---|

| Cast Iron | Heavy traffic, city roads | High strength |

| Ductile Iron | Long life, busy highways | Flexibility, strength |

| FRP | Wet, chemical areas | Corrosion resistance |

| Composite | Parks, sidewalks, green sites | Lightweight, eco-friendly |

The team must check the loading needs for each site. They should know the load rating for the area. For example, a sidewalk needs a lower load rating than a busy street. The team should look at the load capacity of each manhole cover grating. This number tells how much weight the cover can hold without breaking. The right loading class keeps people and vehicles safe.

Find out the expected traffic and weight for the area.

Choose a cover with a load rating that matches or exceeds the need.

Check the load capacity listed by the manufacturer.

Make sure the cover meets standards like EN 124 or ASTM.

Test the cover after installation to confirm it handles the required loading.

Note: Picking the wrong loading class can lead to accidents or early damage.

Choosing the correct size for a manhole cover grating is important for safety and function. The right size keeps the cover secure and stops accidents. Engineers and builders always check the size before they order or install a cover.

Key Steps to Determine the Right Size:

Measure the Opening

Workers use a tape measure or a measuring rod to find the clear opening of the manhole. They measure the inside diameter for round covers or the length and width for square or rectangular covers. They write down the numbers and check them twice.

Check the Frame

The frame holds the cover in place. The cover must fit the frame exactly. If the frame is old or damaged, it may need repair or replacement. A cover that does not fit can move or fall in.

Consider the Shape

Most manhole covers are round, but some are square or rectangular. The shape must match the frame and the opening. Round covers do not fall in easily and are common in cities. Square covers work well in special places like sidewalks or parks.

Standard vs. Custom Sizes

Many projects use standard sizes. These sizes are easy to find and replace. Common round covers measure 24 inches in diameter. Square covers often measure 12, 18, or 24 inches on each side. Some projects need custom sizes for special frames or unique locations. Factories can make covers in any size or shape if needed.

Check the Depth and Thickness

The thickness of the cover affects its strength. Heavy-duty covers are thicker and can hold more weight. The depth of the frame also matters. A deep frame holds the cover better and keeps it from moving.

Table: Common Manhole Cover Sizes

| Shape | Standard Size (inches) | Typical Use |

|---|---|---|

| Round | 24, 30, 36 | Roads, city streets |

| Square | 12, 18, 24 | Sidewalks, parks |

| Rectangular | 12x24, 24x36 | Utility vaults, trenches |

Tip: Always measure the actual opening, not just the old cover. Dirt or rust can change the size over time.

Checklist for Size Selection:

Measure the opening twice.

Match the cover to the frame.

Pick the right shape.

Choose standard or custom size as needed.

Check the thickness for load needs.

A cover that fits well keeps people safe and makes maintenance easy. The right size also helps the cover last longer and work better in all weather.

Picking the right manhole cover grating means you must match the load rating, material, and size to what your project needs. The table below gives important safety and rule tips for each area:

| Area | Safety & Compliance Tips |

|---|---|

| Residential & Sidewalks | Use anti-slip surfaces, make sure water drains well, and pick the right load rating. |

| Highways | Choose strong materials, use secure locks, and get a high load rating. |

| Industrial | Pick covers that resist chemicals, are easy to clean, and drain water well. |

| Airports | Use covers that resist fire, control smells, and follow strict rules. |

Talking to experts helps teams pick the best materials, follow the rules, and stop expensive mistakes. Always use the checklist for every project. This keeps people safe and makes sure you meet all the rules.

A solid manhole cover stops water, dirt, and smells. A grating has holes that let water and air move through. Engineers pick solid covers to seal things. They use gratings for drainage or letting air in.

Workers need to check manhole cover gratings two times each year. Busy roads may need more checks. Regular checks help stop accidents and keep covers working well.

Yes, workers can use coatings like epoxy or bitumen. These coatings help stop rust and chemical damage. Covers with coatings last longer in wet or tough places.

Composite manhole covers can hold cars and trucks if they have the right load rating. Always look at the maker’s details and pick the right class for the traffic.

Patterns and raised surfaces help shoes grip better. They stop people from slipping when covers are wet. Many cities want anti-slip designs to keep people safe.

Workers should measure the opening and frame again. They must use a cover that matches the size and shape. If the frame is broken, they should fix or change it before putting in a new cover.