Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Steel, concrete, and FRP manhole covers each come with their own pros and cons for cities. Steel covers are strong and versatile in design, but they rust and require frequent maintenance. Concrete covers blend well with their surroundings and can support heavy loads, yet they crack easily and need machinery for installation. FRP manhole covers and gratings are gaining popularity in sewer applications because they don’t rust, are lightweight, and are less likely to be stolen. In 2023, the global market for FRP manhole covers reached $1.2 billion, reflecting rapid growth as cities seek more affordable and low-maintenance options. For busy roads, experts recommend ductile iron or composite covers. Ultimately, choosing the best material depends on weighing the pros and cons of each type.

Steel manhole covers are very strong and last a long time. But they can rust. They are heavy and noisy. People often steal them.

Concrete covers look good with the area and cost less. But they are very heavy. They can crack. Machines are needed to put them in.

FRP covers are light and do not rust. They are safe and hard to steal. But they cost more. They cannot hold as much weight as steel.

Picking the right cover depends on how much traffic there is. It also depends on weather, theft risk, and budget. This helps keep people safe and covers strong.

FRP covers save money over time. They need less fixing and are stolen less. This makes them good for many city places.

Steel manhole covers help cities in many ways.

They can hold a lot of weight. Ductile iron is strong and works well for busy roads.

These covers do not break easily when hit or bumped. This helps stop accidents.

Steel is stronger than many other materials. It does not break or bend easily.

Ductile iron covers are strong but not too heavy. Workers can move and install them more easily.

Steel covers last a long time because they are tough.

Stainless steel covers work well in places with salt or chemicals. Grades 304 and 316 do not rust or get damaged by chemicals. Watertight covers keep water and chemicals out.

Many cities use steel covers for busy streets and factories because they last long and work well.

Tip: To learn more about manhole covers, visit JSCA Composite’s product page.

Steel manhole covers also have some problems.

Steel and cast iron covers can rust if they get wet or are near salt. Rust means more repairs and higher costs. Steel covers are worth money when recycled. People sometimes steal them to sell. Missing covers can be dangerous for people and cars.

Steel covers can be noisy when cars drive over them. The sound can bother people living nearby.

Some steel covers are very heavy. They are hard to open and can hurt workers.

Here is a table that shows the main problems:

| Disadvantage | Explanation |

|---|---|

| Theft susceptibility | Steel and cast iron covers are worth money, so people steal them. |

| Corrosion | Steel and cast iron covers can rust over time. |

| Noise | Cars driving over covers can make loud sounds. |

| Mechanical issues | Some steel covers are big, heavy, and hard to open. |

Cities need to think about these good and bad points before choosing steel covers. For more information about other materials, visit JSCA Composite’s About Us page.

Concrete manhole covers help cities in many ways.

These covers match sidewalks and roads well. People like how they look in public places.

Concrete covers can hold heavy things. Trucks and buses can drive over them without breaking most of the time.

Concrete does not rust. Rain and chemicals do not make it corrode, so covers last longer in wet spots.

Concrete covers cost less than steel or FRP covers. Cities save money when they use them for big jobs.

Thieves do not want concrete covers. People do not steal them for scrap.

Concrete covers come in many shapes and sizes. Cities can use them in different places.

Some covers have surfaces that stop people from slipping. This keeps people safer when they walk on them.

Note: To learn more about cover types, visit JSCA Composite’s product page.

Concrete covers have some problems cities should think about.

These covers are very heavy. Workers need machines to lift and put them in place.

Concrete covers cannot hold as much weight as steel. Heavy trucks can damage them over time.

Concrete cracks and chips easily. When trucks or buses drive over them a lot, covers can break.

Concrete covers need to be checked and fixed often. Cracks and chips let water in and cause more damage.

FRP covers need less care than concrete covers. FRP covers do not rust and need little fixing.

Concrete covers can be slippery when wet, even with special surfaces.

Fixing concrete covers takes time and costs money. Cities need to plan for these extra costs.

| Disadvantage | Description |

|---|---|

| Heavy weight | Hard to move and install; needs machines |

| Prone to cracking | Can break or chip if heavy things drive over |

| Regular maintenance | Needs to be checked and fixed often |

| Limited load capacity | Not as strong as steel covers for lots of traffic |

For more about concrete and other covers, check the JSCA Composite About Us page or see customized smart manhole covers.

The good and bad points of concrete covers help cities choose what works best. Some cities use concrete covers in places with less traffic or where theft is a worry. Other cities pick different covers for busy roads or places with lots of trucks.

FRP manhole covers help cities and companies in many ways. These covers are special because of what they are made from and how they work.

FRP manhole covers are very light. Workers can pick them up and put them in place without big machines. This saves time and money. FRP covers weigh much less than steel covers, so they are easy to move.

These covers do not rust or break down when they touch water, salt, or chemicals. This makes them good for places near the ocean, in factories, or at water plants. They last a long time, sometimes over 25 years, and do not need much fixing.

FRP manhole covers have a surface that helps stop people from slipping. Even when it is wet, people are less likely to fall. This keeps workers and people walking safe.

FRP manhole covers do not carry electricity. This means they are safe to use near wires or electric places. It helps stop shocks and fires in subways or factories.

These covers can be made in different sizes, colors, and shapes. Cities can make them match roads or sidewalks. They can also add logos or marks to help people know what they are for.

FRP manhole covers are not worth money as scrap. Thieves do not want to steal them. Cities that use FRP covers see theft go down to almost none.

FRP manhole covers do not need much care. They do not need paint or lots of cleaning. Their strong material means cities spend less on repairs.

Note: To learn more about FRP manhole covers and where they are used, visit the JSCA Composite FRP Manhole Cover product page or check out the JSCA Composite homepage.

| Feature | Benefit |

|---|---|

| Lightweight | Easy to handle and install; reduces labor costs |

| High corrosion resistance | Withstands water, salt, and chemicals; long-lasting |

| Slip resistance | Prevents accidents in wet conditions |

| Non-conductivity | Safe for electrical and high-voltage environments |

| Customization | Fits project needs; allows for logos and markings |

| Low theft risk | No scrap value; unattractive to thieves |

| Low maintenance | Rarely needs repairs or painting |

FRP manhole covers also have some problems that cities and builders should think about.

FRP manhole covers cost more to buy than steel or concrete covers. The higher price can make big projects cost more money.

These covers are strong for their weight, but they cannot hold as much weight as steel covers. Heavy trucks or busy roads may need stronger covers. FRP covers work best for sidewalks, walking areas, and light cars.

FRP manhole covers can get damaged by sunlight. Makers put special coatings on them, but after a long time, the sun can still make them fade or wear out. This is important for covers used outside.

Some cities may have trouble finding enough FRP covers or getting special sizes. There are not as many companies making custom FRP covers as there are for other types. This can make it take longer to get the covers for special jobs.

| Disadvantage | Description |

|---|---|

| Higher initial cost | More expensive than steel or concrete at purchase |

| Limited load capacity | Not suitable for heavy-duty or high-traffic roads |

| UV sensitivity | Needs UV-resistant coatings for outdoor use |

| Availability | Fewer suppliers for custom designs in some regions |

Tip: To find out more about FRP manhole covers, their good and bad points, and how they compare to other covers, visit the JSCA Composite About Us page.

FRP manhole covers are light, do not rust, and are not stolen. They work well in places with lots of chemicals, near electricity, or where theft is a problem. But cities should think about the higher price and weight limits before picking FRP manhole covers for their needs.

Picking the best manhole cover is important. Each type—steel, concrete, and FRP—has good and bad sides. The table below shows how they are different. This helps cities and workers pick what works best for them.

| Attribute | Steel (Cast Iron Manhole Cover) | Concrete Manhole Cover | FRP Manhole Cover |

|---|---|---|---|

| Strength | Very strong; holds heavy things; used on roads | Strong; holds some heavy things; can crack if too much weight | Strong for its weight; fits many uses; best for light or medium traffic |

| Weight | Very heavy; hard to move; needs machines | Heavy; needs tools to put in place | Light; easy to carry and put in by hand |

| Cost | Costs a lot or a little; depends on size and type | Cheapest at first; $20–$80 each | Costs more at first; $10–$50 per square foot; saves money later |

| Durability | Lasts long but can rust; needs care | Lasts but can crack or chip; does not rust much | Does not rust; lasts a long time; needs little care |

| Safety | Heavy covers can hurt workers; rust makes them weak | Heavy; can crack; can be slippery when wet | Not slippery; does not carry electricity; safer for workers |

| Maintenance | Needs lots of checks for rust and breaks | Needs fixing for cracks and chips | Hardly needs fixing; easy to clean; not much work |

| Theft Risk | Easy to steal; people sell them for money | Not stolen much; too heavy and not worth money | Not stolen; not worth money; good for places with theft |

Note: Cities use a cast iron manhole cover on busy roads because it is strong. But people steal them a lot. Now, many cities use FRP covers where theft happens often. For more, see cast iron manhole covers and FRP manhole covers.

A cast iron manhole cover is strong but rusts in wet or salty places.

Concrete covers are cheaper but break easier and need machines to move.

FRP covers last longer in tough places and are strong, even with chemicals or salt.

If a cast iron manhole cover is stolen, it is dangerous. People can fall in or sewers can get blocked.

Cities often switch from a cast iron manhole cover to FRP covers to stop theft and save on repairs.

For water grates and other products, see water grates.

Tip: Always pick the right manhole cover for the place. A cast iron manhole cover is good for highways. FRP covers are better where theft or chemicals are a problem.

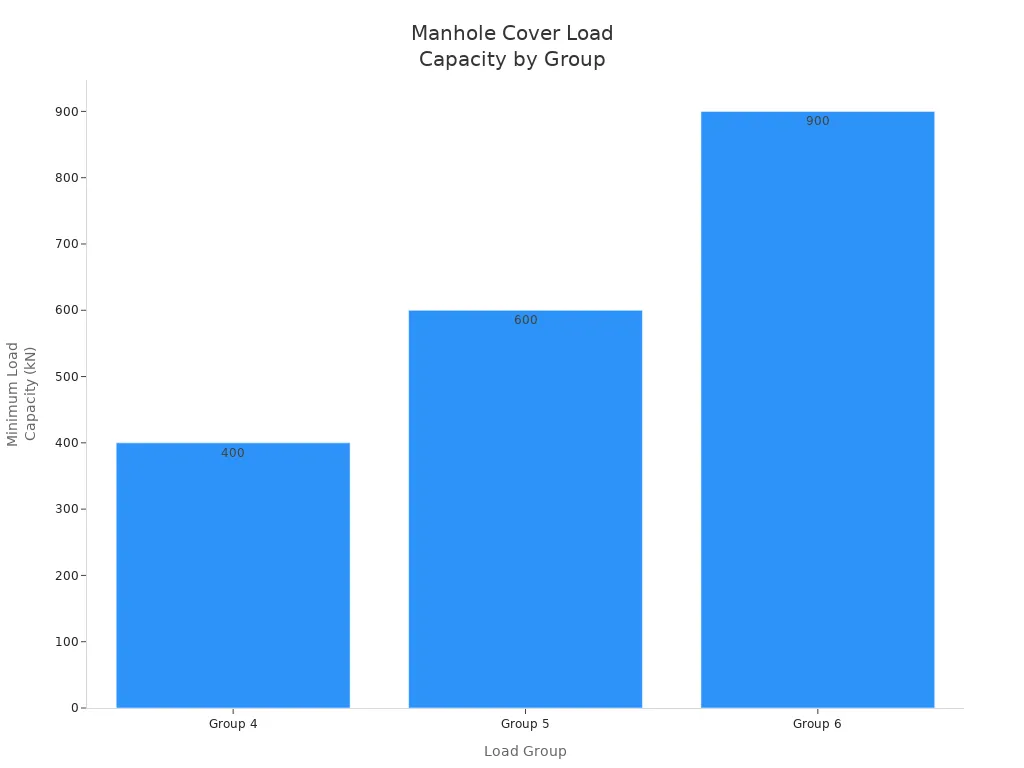

Picking a manhole cover starts with knowing where it goes. City planners look at how busy the area is. They check what kind of cars or trucks drive over the cover. Busy roads, airports, and docks need covers that hold heavy loads. Ductile iron covers are best for these places. They are strong and last a long time. The table below shows which covers work for each place:

| Load Group | Typical Application Area | Minimum Load Capacity | Recommended Material |

|---|---|---|---|

| Group 4 | Heavy-duty roads and motorways | 400 kN (D400) | Ductile iron |

| Group 5 | Areas with high wheel loads (e.g., docks) | 600 kN (E600) | Ductile iron |

| Group 6 | Very high wheel loads (e.g., airports) | 900 kN (F900) | Ductile iron |

Sidewalks, parks, and quiet streets can use lighter covers. FRP manhole covers or concrete covers work well here. These covers are easy to put in and save money on labor. Covers with anti-slip surfaces help keep people safe. Locking covers stop people from opening them without permission. Cities should check rules before picking a cover.

Weather and location matter when picking covers. Places near the ocean or chemical plants need covers that do not rust. Iron covers need special coatings, but these wear off. Ductile iron is better than cast iron, but still needs care. FRP manhole covers do not rust or break down. They work well in places with chemicals, salt water, or lots of rain. FRP covers also stand up to sun and heat. This makes them good for sewers and drains in cities. Concrete covers do not rust but can crack in bad weather or with chemicals. In wet or harsh places, composite covers last longer and are easier to take care of. To learn more, contact the company experts.

Money and care matter when picking covers. FRP manhole covers cost more at first. But they save money later because they last longer. They are light, so workers can install them easily. FRP covers do not rust, so cities fix them less often. Cities with small budgets like FRP covers because they need little care. Concrete covers cost less at first but need more repairs. Steel covers are strong but need checks to stop rust. FRP covers are not stolen much, so cities save money. Cities that want to save money often pick FRP covers. For more help, visit the FRP Manhole Cover product page.

Tip: Always think about the good and bad sides of each cover. Look at traffic, weather, money, and care needs to pick the best one for your project.

Steel, concrete, and frp manhole covers all have good and bad points. Steel covers are very strong but need to be checked and fixed often. Concrete covers last a long time but are very heavy and can break. Frp manhole covers are light, do not rust, and are not stolen. The table below shows how they are different:

| Feature | Steel | Concrete | FRP |

|---|---|---|---|

| Weight | Heavy | Very heavy | Lightweight |

| Lifespan | 15–25 yrs | 10–15 yrs | 30–50 yrs |

| Theft Risk | High | Low | None |

When picking a cover, think about how much weight it needs to hold, the weather, and if theft is a problem. You can use the comparison table and guidance to help you choose the safest and longest-lasting cover.

FRP manhole covers do not rust and last a long time. Cities like them because they are light and hard to steal. These covers are easy to put in and take care of.

A cast iron manhole cover is strong and holds up heavy traffic. Concrete covers cost less but break easier. Cast iron covers need more fixing because they can rust.

Cities pick lightweight manhole covers for places with less traffic. These covers are quick to put in and simple to move. Workers save time and are less likely to get hurt.

FRP manhole covers do not rust and are not stolen. They last a long time and need little fixing. They cost more at first and cannot hold as much weight. Their rust-proof design makes them good for sewers and drains.

High resistant manhole covers need fewer repairs. Cities save money and time with covers that are easy to care for. FRP covers and cast iron covers are both strong, but FRP covers need less checking.