Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

Manhole covers are plates you can take off. They work as lids for manholes. These covers keep people from falling in. They also stop people who should not enter. This helps keep everyone safe in busy places.

Gratings are flat pieces made of metal or other materials. They go over holes to let water flow through. Gratings stop trash and accidents from happening.

Manholes let workers get to pipes and vaults underground. Workers use them to check and fix things.

Picking the right manhole covers and gratings keeps people safe. It also helps follow rules. This makes it easier for engineers and city workers to talk clearly.

Manhole covers are strong plates that cover holes underground. They keep people safe from falling in. Gratings have holes so water can go through. Gratings also stop trash from going down.

You need to pick the right manhole cover or grating. This depends on the load class. Load class tells how much weight the cover can hold. Some are for people walking. Others are for heavy cars and trucks.

Materials like ductile iron and composite are very strong. They do not rust easily. These materials are good for wet places or places used a lot.

Manhole covers and gratings must follow safety standards. EN124 and ASTM are examples of these rules. These rules make sure covers are strong and safe for their jobs.

Using the right words and knowing cover parts is important. It helps workers talk clearly. It also keeps public spaces safe.

Knowing the words for manhole covers and gratings helps people in building, engineering, and city work. The next parts explain the main words and show how different places use different names.

A manhole cover is a strong plate that goes over a hole. These covers keep people safe and stop others from going underground. Most manhole covers are round. Some are square or rectangle. Round covers do not fall into the hole. In the United States, people usually say “manhole cover.” Some places use “maintenance hole cover” to include everyone. Utility companies might say “utility hole cover.” In California, some cities use “maintenance hole cover” as the official name.

Tip: Use “manhole cover” or “maintenance hole cover” when talking about covers for underground spaces. This helps people not get mixed up with other covers.

Here is a table with other names and how people use them:

| Term | Region/Context | Description/Notes |

|---|---|---|

| Manhole Cover | USA (general) | Traditional term for covers over human-sized underground access. |

| Maintenance Hole Cover | California, USA | Gender-neutral alternative, now official in some cities. |

| Utility Hole Cover | USA (utility industry) | Used for access to water, gas, or sewage utilities. |

| Hand Hole Cover | USA (industry) | Smaller covers for visual inspection or small equipment. |

| Sewer Cover | USA, UK | Used for sewer systems, sometimes labeled. |

| Access Port Cover | General | Emphasizes the function of providing underground access. |

| Inspection Chamber Cover | UK, other regions | Used for frequent inspection access. |

To see more about types of manhole covers, visit this product page.

Gratings are flat panels with holes. Water can go through, but big trash cannot. People see gratings on storm drains or catch basins. The right word is “grating,” not “grading.” “Grading” means making a surface flat. “Grating” means the metal or plastic mesh cover. Many students and new workers mix up these words. Using the right word helps everyone understand.

Gratings come in many shapes and materials. Some are made of cast iron. Others use composite materials. Gratings are used in drainage systems. They help water move off streets and sidewalks. Learn more about water grates here.

A manhole is an underground room. Workers use it to reach pipes, water, or electric lines. The manhole is the space under the cover. Workers go inside to check, clean, or fix pipes and cables. Some places call these “maintenance holes” or “utility holes.” The cover on top keeps the manhole safe.

An access cover is any plate you can remove to get underground or into a utility box. You find access covers over manholes, cable trenches, or water meters. They come in many shapes and sizes. Some are made for heavy cars. Others are just for people walking. See examples of access covers here.

Note: People use “access cover” for covers that are not part of a manhole, like covers for electric or plumbing systems.

A catch basin is a box that collects rainwater. It sends water into the drain system. The top has a grate or cover. Catch basin grates stop big trash from going into the pipes. These grates help water flow and stop blockages. Some people call them “storm drain covers” or “surface water drain covers.” Find more about catch basin grates here.

A drain cover is a plate or grate over a drain. People use drain covers to keep trash out and stop accidents. The words “drain cover” can mean different things. Sometimes it is a small cover in a sink or shower. Other times, it is a big grate in the street. This can confuse students and new workers. Makers and engineers call big outdoor covers “storm grates” or “manhole covers.” Small indoor covers are just “drain covers.”

Tip: Always check what someone means by “drain cover.” It could be a small indoor cover or a big outdoor grate.

People use many names for manhole covers and gratings in different places. Here is a table with some of these names:

| Category | Terms / Alternative Names | Description / Regional or Standard Notes |

|---|---|---|

| Shape | Round manhole cover | Most common, standardized since 1860s, safer as it cannot fall into hole; used in city streets, sidewalks, public areas. |

| Square manhole cover | Popular in commercial/utility infrastructure; easier to lift and align; used in electrical vaults, telecom systems. | |

| Rectangular manhole cover | Used in trenches, railways, industrial sites; offers larger access; may have hinged openings. | |

| Material | Cast iron manhole cover | Oldest type; strong but brittle; used in low to medium traffic areas. |

| Ductile iron manhole cover | Stronger, flexible, corrosion-resistant; suitable for highways, airports, industries. | |

| Concrete manhole cover | Affordable, used in low-traffic areas; reinforced with steel or fibers; theft-resistant. | |

| Fiberglass manhole cover | Lightweight, corrosion-resistant, non-conductive; used in chemical, industrial, or sanitary environments. | |

| Stainless steel manhole cover | Corrosion-resistant, aesthetic; used indoors or low-traffic areas. | |

| Load-Bearing Capacity | Lightweight manhole cover | For pedestrian areas; made of fiberglass, composite, or light concrete; meets load classes A15 or B125. |

| Heavy-duty manhole cover | For highways, airports; meets standards D400, E600, F900; made of ductile iron, cast iron, or reinforced concrete. | |

| Functionality | Lockable manhole cover | Includes locking mechanisms for security; used in sensitive areas like airports, military bases. |

| Watertight manhole cover | Sealed with rubber/polymer gaskets; prevents water ingress; used in flood-prone or coastal areas. | |

| Alternative Names | Drain cover | Covers smaller surface water inlets; limits debris entry; smaller and lighter than manhole covers. |

| Standards Referenced | ASTM F1142, ASTM F1143, ASTM F1144, EN 124 | Standards regulating manhole covers in different regions (US and EU). |

To learn more about different covers, visit this page.

Manhole covers and gratings both protect holes in the ground. But they do different jobs. A manhole cover is a solid plate. It blocks entry and keeps people safe. It covers a manhole that workers use. A grating has holes that let water pass through. Gratings are used in storm drains and catch basins. They help stop floods by letting water in but keeping trash out.

Remember: Use “manhole cover” for solid lids over access points. Use “grating” for covers with holes that let water go through.

If you want to know more about inspection manhole covers or smart covers, check out these products and here.

Manhole covers and gratings come in many kinds. Each kind has its own job in storm and drain systems. The most common shapes are round, square, and rectangular. These shapes help them fit in different places in cities. Manhole covers are often made from ductile iron. This makes them strong and long-lasting. Some covers use composite or plastic. These are lighter and used for smaller loads.

A solid top manhole cover stops water and trash from getting in. This type is good for places where water should not go through. Solid covers are usually round or square. You can find them in busy areas and places with lots of cars. See solid top manhole covers here.

Recessed manhole covers let you put paving or tiles inside them. This helps the cover look like the sidewalk or driveway. These covers are used in homes and service areas. They are made for light or medium weight. They are not for heavy traffic.

Ventilated covers have holes or slots in them. These let air and some water pass through. They help stop gas from building up under the cover. People use ventilated covers where airflow is needed.

Storm drain covers, also called storm drain grates, have open slots or bars. These let rainwater go into the drain but block big trash. Storm drain covers are important for streets, parking lots, and highways. Find storm drain covers here.

Sump covers keep sump pits safe and stop things from falling in. These covers can be solid or have holes. Sump covers are found in basements, pump stations, and storm water systems. They help keep the drain clean and safe. Explore sump covers here.

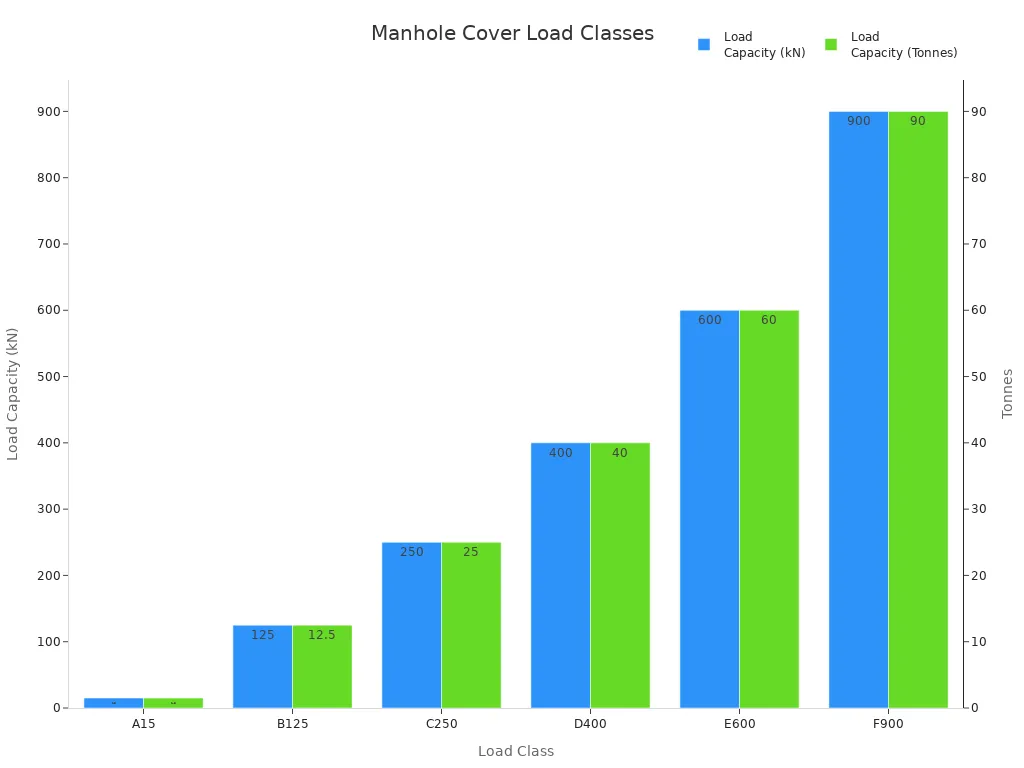

Manhole covers, storm drain covers, and sump covers must meet different weight rules. Load classes show how much weight each cover can hold. The table below lists common load classes and where they are used:

| Load Class | Load Capacity (kN) | Load Capacity (Tonnes) | Typical Application / Traffic Specification |

|---|---|---|---|

| A15 | 15 | 1.5 | Pedestrian areas, gardens, sidewalks |

| B125 | 125 | 12.5 | Car parks, driveways, light vehicle access |

| C250 | 250 | 25 | Roads with light traffic |

| D400 | 400 | 40 | Main roads, highways, heavy traffic |

| E600 | 600 | 60 | Industrial estates, cargo yards |

| F900 | 900 | 90 | Airports, docks, extra heavy duty |

Covers for walking areas are called non-traffic covers. Light duty covers are used on sidewalks and in gardens. Heavy duty covers, like those for h-20 or hs-20 loading, are for city roads and trucks. Extra heavy duty covers, such as those in airports, meet F900 loading needs. Sump covers and storm drain covers must have the right load class to keep people safe.

Manhole covers and gratings are made from different materials. Each material has special benefits for safety and how long it lasts. These materials help covers work well in many places.

Cast iron is a common choice for manhole covers and gratings. It is strong and lasts a long time. This makes it good for busy roads and heavy traffic. Cast iron does not rust easily. It can have patterns or logos on it. But cast iron is heavy and costs more money. People sometimes steal it because it is worth a lot as scrap. Cast iron covers need regular care to stay in good shape.

| Material | Advantages | Disadvantages |

|---|---|---|

| Cast Iron | Strong, durable, corrosion-resistant | Heavy, costly, prone to theft |

Ductile iron is better than cast iron in some ways. It is stronger and can take more hits. It works well for heavy loads and lots of use. Ductile iron covers last longer and do not crack easily. They cost more than cast iron but are tougher. Ductile iron covers often get special coatings to stop rust and last longer.

| Property | Ductile Cast Iron Characteristics | Impact on Durability and Use |

|---|---|---|

| Tensile Strength | >420 MPa | High strength for drain covers |

| Toughness | 10x gray cast iron | Reduces breakage risk |

| Corrosion Resistance | 0.1x gray cast iron | Longer service life in drain systems |

Composite materials like fiberglass are now used for covers and gratings. These covers are light and do not rust. They are easy to move and put in place. Thieves do not want them because they have no scrap value. Composite covers stand up to chemicals in drain water. They last longer in tough places. Making composite covers uses less energy and makes less pollution. They do not carry electricity, so they are safe for electric and steam drains. See composite manhole covers here.

Composite covers are a good choice for new drain systems.

Steel covers and gratings are used where extra strength is needed. Stainless steel is the most popular type in the world. It does not rust and is very strong for its weight. Steel covers do not crack and can hold heavy things. They need care to stop rust, especially in wet places.

People make manhole covers and gratings in different ways. Cast iron and ductile iron covers are made by melting metal and pouring it into molds. Composite covers are made by shaping fiberglass and resin together. Some covers use recycled stuff to help the environment. New ways of making covers help them last longer and keep people safe. Explore composite manufacturing options here.

Manhole frame and cover systems keep underground utilities safe. They also let workers get in safely. Each part has a job. Some parts help hold weight. Others make it safer for people. All parts work together to give good access.

The frame is the bottom part for the cover. Makers use cast iron, concrete, or both to make frames. These materials make the frame strong and tough. The frame sits at ground level. It matches the hole’s shape. The frame holds the cover and spreads out weight from cars or people. Many frames have grooves or slots to stop slipping. For more about frames, visit JSA Composite.

The lid is the top part that covers the manhole. It keeps trash out and keeps people safe. Lids can be made from cast iron, steel, plastic, or composite. Workers can take off the lid to get inside. Some lids have rough surfaces to stop slipping. Lids must be strong to hold up heavy things like cars.

A captive hinge links the lid to the frame. This hinge keeps the cover from getting lost or stolen. It also stops the lid from falling into the manhole. Captive hinges help workers open the lid more easily.

Bearer bars help hold up the cover. They spread out the weight on the frame. These bars make the cover stronger. Bearer bars help the cover handle heavy loads from cars.

Seating is where the frame and cover touch each other. Good seating makes sure the cover fits tight. This stops the cover from moving. Good seating keeps the frame and cover safe when weight is on them.

Locking parts stop people who should not open the manhole. Locks keep the cover safe from being stolen. Many covers have special locks to stop vandals. These locks protect the utilities and keep people safe. Learn more about locks at JSA Composite.

Anti-slip parts are grooves, slots, or rough spots on the cover. These help stop people from slipping, even when it is wet. Anti-slip surfaces make it safer for people and workers. Some covers have special coatings for better grip.

Watertight covers use seals or gaskets to keep water out. These seals protect wires and pipes under the ground. Watertight covers stop water from getting in and causing damage. Flexible sealants and coatings give extra safety.

Lifting points are handles or slots on the cover. Workers use these to lift the cover safely. Good lifting points help stop injuries and make work easier. Some covers have two layers of cables for safer lifting. For more about lifting, see Inspection Manhole Covers.

Tip: Check and fix manhole frame and cover parts often. This helps stop accidents and makes them last longer.

Manhole structures also have parts like the chimney, cone, barrel, steps, invert, and channel. These parts help hold up the frame, guide workers, and move water. For more about manhole systems, visit JSA Composite.

Knowing standards and abbreviations helps people pick the right manhole covers and gratings. These rules make sure covers are strong enough. They help keep people safe. Engineers and workers use these rules to check if a cover can hold enough weight. Abbreviations help teams talk clearly. This stops mistakes.

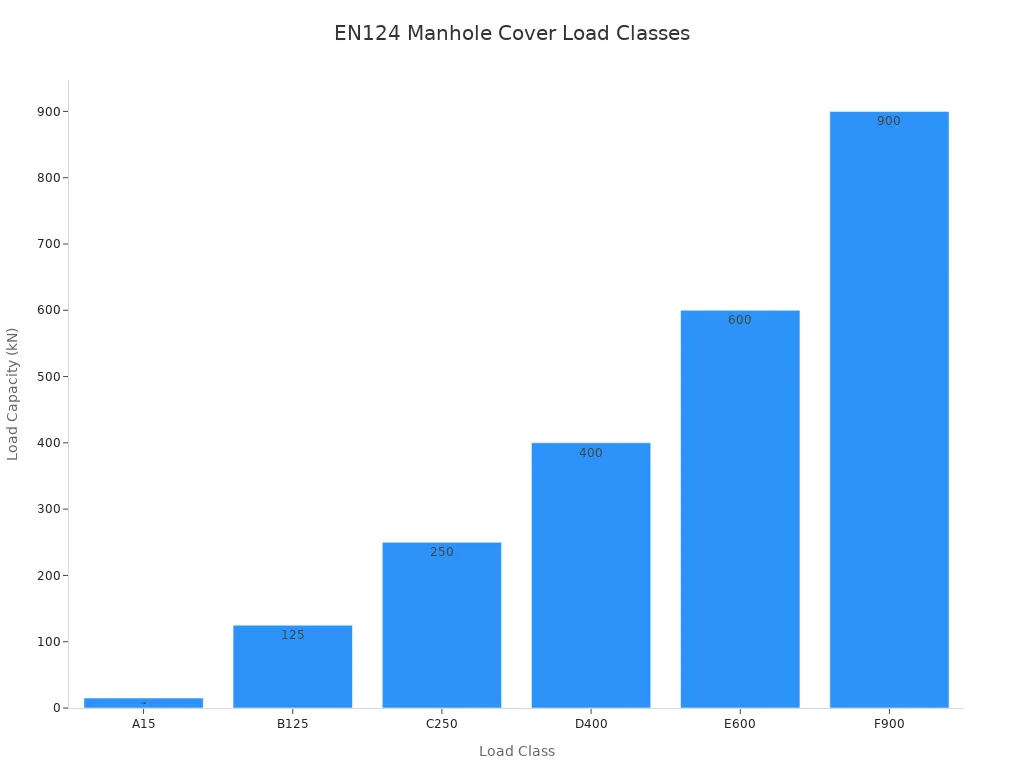

EN124 is a rule used in Europe and Britain for manhole covers and gratings. It tells how much weight each cover should hold. EN124 uses load classes. Each class fits a different need, like walking or heavy trucks. The rule also says where to use each class, such as sidewalks or airports.

| Classification Aspect | Description |

|---|---|

| Standard Name | BS EN 124:2015 (European and British standard) |

| Scope | Says what manhole covers, access covers, and gully gratings need in places with cars or people |

| Classification Basis | Tests how much weight covers can hold (in kN) |

| Load Classes | A15 (15 kN), B125 (125 kN), C250 (250 kN), D400 (400 kN), E600 (600 kN), F900 (900 kN) |

| Installation Groups | Group 1: Only for peopleGroup 2: Car parks and places with some carsGroup 3: Slow traffic areasGroup 4: Roads and parkingGroup 5: Heavy wheel placesGroup 6: Very heavy wheel places |

| Material Parts | General part plus five parts for different materials (cast iron, steel/alloys, reinforced concrete, composites, plastics) |

| Purpose | Helps pick covers and gratings that are safe and last long for the right place and weight |

EN124 matches each load class to the right spot. For example, A15 is for sidewalks. F900 is for airports. The rule uses two kinds of tests to check covers. This makes sure covers can hold the weight they need.

| Class | Typical Use | Nominal Wheel Load (kg) | Serviceability Design Load (kN) | Ultimate Limit State Design Load (kN) |

|---|---|---|---|---|

| A15 | For people and bikes | 330 | 10 | 15 |

| B125 | Walkways, car parks | 2670 | 83 | 125 |

| C250 | Road edges | 5000 | 167 | 250 |

| D400 | Roads and parking | 8000 | 267 | 400 |

| E600 | Heavy wheel places | 20000 | 400 | 600 |

| F900 | Very heavy wheel places | 30000 | 600 | 900 |

EN124 helps people pick covers that fit the right weight. This keeps roads, sidewalks, and airports safe.

ASTM rules are used in North America and other places. These rules make sure manhole covers and gratings are strong enough. ASTM A48 checks grey iron and ductile iron covers. ASTM A36 is for steel rings. ASTM A123 gives rules for coating steel. These rules check if covers can hold heavy things, take hits, and last long.

ASTM A48 checks if cast iron covers can hold heavy weight and take hits.

ASTM A36 is for steel parts. It makes sure they are strong for heavy loads.

ASTM A123 tells how to coat steel so it does not rust.

ASTM rules work with EN124 to match load classes like D400 or F900.

These rules help covers pass tests for safety.

ASTM rules help companies follow safety and export needs.

ASTM rules make sure covers can hold the right weight and keep people safe.

Note: Rules like EN124 and ASTM say covers must pass tests for weight and strength. This keeps people safe and protects cities.

Abbreviations help workers and engineers talk about manhole covers and gratings. These short forms save time and help stop mistakes when talking about weight and where covers go.

MH: Manhole

MC: Manhole Cover

CB: Catch Basin

CI: Cast Iron, Curb Inlet

CIP: Cast Iron Pipe, Cast in Place

CISP: Cast Iron Soil Pipe

CO: Cleanout

CP: Concrete Pipe

CSP: Concrete Sewer Pipe

DMH: Drainage Manhole

EHH: Electrical Handhole

EMH: Electrical Manhole

FH: Fire Hydrant

HH: Handhole

IMH: Inlet Manhole

SDMH: Storm Drain Manhole

SMH: Sewer Manhole

SS: Sanitary Sewer, Sewer Service, Stainless Steel, Storm Sewer

SWR: Sewer

TMH: Telephone Manhole, Top of Manhole

Tip: Always check what abbreviations mean before starting work. This helps teams work together and keeps everyone safe.

To learn more about rules, weight, and safe setup, visit JSA Composite’s homepage, about us, or contact page.

Knowing the words for manhole covers and gratings helps civil engineers do their jobs. It lets them pick the right materials and follow the rules. This keeps covers safe and makes sure they fit the right shape and weight. It also helps when checking, fixing, or taking care of covers. This keeps parks, streets, and other places safe for everyone. Using the glossary helps workers and the public stay safe. If you want to learn more or get extra safety tips, check out these links:

A manhole cover is a solid lid. It blocks people from going underground. A grating has holes that let water pass through. Gratings stop big trash from falling in.

Load classes tell how much weight a cover can take. Engineers choose covers for people, cars, or trucks. Heavy-duty covers meet D400 or F900 rules.

Ductile iron and composite covers do not rust easily. They last longer in wet places. Composite covers are lighter and do not carry electricity.

Anti-slip surfaces help stop slips and falls. This is important when covers are wet. Grooves or rough spots make covers safer for everyone. For covers with anti-slip, check Inspection Manhole Covers.

People can look at products or read details on the website. They can also ask for a quote at JSA Composite’s homepage. The site gives guides and help for picking the right cover.