Views: 0 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

Have you ever wondered how manhole covers and drain grates differ? While they may look similar, each serves a unique purpose in urban infrastructure. Understanding their distinctions is vital for urban planning and safety.

In this article, we will explore the key differences between manhole covers and drain grates, their roles in water management, and the materials used. You’ll gain insights into when and why to choose one over the other.

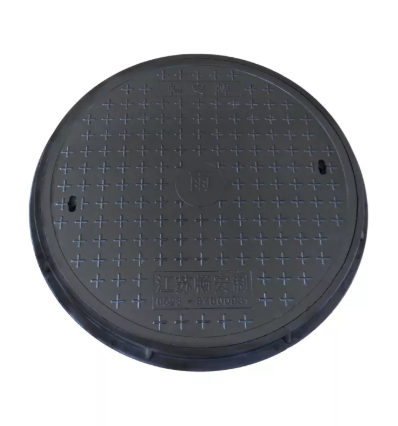

A manhole cover is a solid, heavy-duty plate designed to cover an opening that provides access to underground utilities, such as sewage systems, water pipes, or electrical cables. These covers are crucial in urban environments, protecting people and vehicles from falling into manholes and preventing unauthorized access to sensitive utility networks. Typically round or square, manhole covers are designed to stay securely in place under heavy traffic. They are essential for worker safety and preventing contaminants from entering underground systems, which could result in significant health or environmental hazards.

Manhole covers are primarily designed to:

● Block entry: They prevent accidents by covering access points to underground utilities.

● Protect infrastructure: Keep debris, rainwater, and other external elements out of the system, preventing contamination and ensuring that utilities function properly.

In contrast, a drain grate is a slotted or perforated cover designed to allow the flow of water into drainage systems while preventing larger debris from clogging the pipes. Drain grates are commonly found on sidewalks, streets, parking lots, and areas prone to water accumulation, where they help manage surface water. Their primary function is to control water runoff and prevent flooding by allowing water to pass through while blocking leaves, trash, or other solid materials that could obstruct the flow. Drain grates play an essential role in maintaining safe and dry streets, parking lots, and walkways, particularly during periods of heavy rain.

Drain grates are typically designed to:

● Allow water flow: They channel rainwater and runoff into drainage systems, helping to prevent flooding and water damage.

● Prevent debris entry: By using a slotted or mesh structure, they keep large particles from clogging the system, ensuring smooth and efficient water flow.

Feature | Manhole Covers | Drain Grates |

Design | Solid, heavy plate | Slotted or perforated grid |

Primary Function | Provides access to underground utilities | Allows water flow while preventing debris entry |

Common Materials | Cast iron, ductile iron, composite | Steel, aluminum, polymer concrete |

Load-Bearing Capacity | High (e.g., D400, E600) | Lower, focused on water management |

Installation Locations | Roads, highways, sewer entries, utility vaults | Street curbs, parking lots, sidewalks, stormwater systems |

Purpose | Prevents unauthorized entry, protects utilities | Manages surface water runoff, prevents flooding |

The key difference between manhole covers and drain grates lies in their design. Manhole covers are solid, typically made from heavy-duty materials like cast iron or ductile iron. Their primary purpose is to block entry to underground spaces while withstanding the weight of vehicles and foot traffic. They are also designed to be secure and durable, ensuring that they stay in place under pressure, preventing accidents or unauthorized access.

On the other hand, drain grates have an open-grid design, which allows water to flow freely into the drainage system. The slots or holes in the grate prevent large debris from entering, which can block the pipes. While manhole covers are heavy and solid to prevent entry, drain grates are lighter and more open to facilitate drainage, making them ideal for areas where water flow needs to be efficiently managed.

Manhole covers are designed to bear significant loads, especially in areas with heavy traffic such as highways, airports, and industrial sites. These covers must withstand the impact of vehicles, including trucks and emergency vehicles, without cracking or shifting. Drain grates, while also needing to support heavy loads, primarily focus on water drainage and debris management, rather than providing access to underground systems.

Material strength and load-bearing capacity vary for both types of infrastructure. Manhole covers are typically rated for higher load classes (e.g., D400 or E600) to handle heavy traffic. Drain grates are rated for lighter loads, though in some areas, such as industrial zones, they may be designed to withstand higher pressures. Choosing the right load-bearing capacity for each is essential to ensure safety and functionality in various environments.

Manhole covers must be incredibly durable to handle heavy traffic and harsh environmental conditions. Common materials used for manhole covers include:

● Cast Iron: Known for its strength and durability, cast iron is one of the most commonly used materials for manhole covers. However, it can be heavy and prone to rusting over time if not properly maintained. It is often used in low to medium-traffic areas where heavy durability is needed.

● Ductile Iron: Offering higher impact resistance and flexibility than cast iron, ductile iron is often used in high-traffic areas. It is more resistant to cracking and rust, which makes it ideal for environments where manhole covers are subject to frequent vehicular traffic.

● Composite Materials: These lightweight alternatives to metal are often used in residential or low-traffic areas. Composite manhole covers are corrosion-resistant and easier to lift, making them ideal for areas where weight is a concern. They are often made from materials like fiberglass or polymer, offering a lighter but durable solution.

Drain grates are typically made from materials that allow for high drainage capacity while also withstanding the load of foot and vehicle traffic. The most common materials for drain grates are:

● Steel: Steel is durable and resistant to corrosion, making it suitable for both urban and industrial settings. Stainless steel is especially useful in areas exposed to saltwater or chemicals, offering excellent strength and long-term durability.

● Polymer Concrete: This material is lightweight, corrosion-resistant, and ideal for environments that require a balance of strength and chemical resistance. It is commonly used in areas where both durability and lightweight features are needed.

● Aluminum: Aluminum is another lightweight material commonly used for drain grates. It is resistant to corrosion and is often used in areas exposed to moisture or mild environmental stress.

Material | Manhole Covers | Drain Grates |

Cast Iron | Durable, strong, corrosion-resistant, heavy | Suitable for high-traffic areas, prone to rust over time |

Ductile Iron | Flexible, impact-resistant, corrosion-resistant | Ideal for high-traffic areas, more resistant to cracking than cast iron |

Composite Materials | Lightweight, corrosion-resistant, easy to lift | Lightweight, corrosion-resistant, ideal for residential areas |

Steel | N/A | Strong, resistant to corrosion, ideal for industrial settings |

Polymer Concrete | N/A | Lightweight, corrosion-resistant, good for chemical environments |

Aluminum | N/A | Lightweight, corrosion-resistant, good for mild environments |

Manhole covers are essential in areas where access to underground utilities is needed for maintenance and repairs. They are typically installed in the following locations:

● Roads and Highways: Manhole covers are commonly found on roads and highways, where access to sewage, water, and electrical systems is required. They must be designed to withstand heavy vehicle traffic, ensuring that the cover remains securely in place even under constant stress.

● Sewer Entries: In sewer systems, manhole covers provide access for cleaning, inspection, and repairs. These covers must be secure to prevent accidents and unauthorized access.

● Telecom and Utility Vaults: Manhole covers are also used to protect vaults that house telecommunications and utility equipment, ensuring safety and accessibility for authorized personnel.

Drain grates are usually installed in areas where water runoff needs to be managed. Common locations include:

● Street Curbs and Gutters: Drain grates along the edge of roads channel water into stormwater systems, preventing flooding and ensuring streets stay dry. These grates are particularly important in urban environments, where water accumulation can lead to significant damage if not properly managed.

● Parking Lots: In parking lots, drain grates help prevent puddles and water accumulation, keeping surfaces safe and clean. These grates also help to maintain the structural integrity of the parking lot, reducing water damage to the pavement.

● Sidewalks and Pedestrian Areas: Drain grates installed in sidewalks and public areas help manage rainwater runoff while ensuring pedestrian safety. These grates are designed to be slip-resistant and durable, making them ideal for areas with high foot traffic.

Installing manhole covers requires careful attention to alignment and sealing. Ensuring that the cover is securely fitted will prevent accidents and unauthorized access. Key steps for proper installation include:

● Sealing: Manhole covers should be sealed to prevent water infiltration and protect the underground system from contamination. Sealing also ensures that the cover remains in place, preventing leaks or the risk of falling debris.

● Securing: Covers must be securely locked in place to prevent them from shifting or being removed. This ensures the safety of workers and the general public.

Regular maintenance is essential to keep drain grates functioning effectively. Best practices for maintaining drain grates include:

● Cleaning: Removing debris, leaves, and other obstructions from the grates regularly will ensure that water flows freely into the drainage system. Clogged drain grates can lead to flooding and water damage.

● Inspection: Inspecting grates for damage or misalignment is crucial to prevent accidents and ensure proper drainage. If a drain grate is cracked or misaligned, it should be replaced to prevent water pooling and pedestrian accidents.

● Replacement: When drain grates are damaged, they should be replaced promptly to avoid water accumulation and potential flooding. Ensure that the replacement grate meets the required load-bearing standards for the area.

Both manhole covers and drain grates are crucial components of urban infrastructure, designed for different purposes. Manhole covers block access to underground systems, ensuring safety and protecting infrastructure. In contrast, drain grates manage water flow, preventing debris from clogging drainage pipes. Understanding these differences is essential for making informed decisions about installation and maintenance, ensuring public safety and optimal functionality.

Jiangsu Chang'an Manhole Cover Co., Ltd. offers high-quality manhole covers that provide durability, safety, and ease of installation. Their products are engineered to withstand heavy traffic and harsh environmental conditions, making them ideal for urban planning projects. With a focus on performance and long-lasting value, Jiangsu Chang'an Manhole Cover Co., Ltd. ensures that their manhole covers support efficient infrastructure development and maintenance.

A: Manhole covers are solid plates that block access to underground utilities, while drain grates are perforated to allow water flow and prevent debris from entering drainage systems.

A: Manhole covers are commonly found on roads, highways, sewer entries, and utility vaults, providing access for maintenance and repairs.

A: Drain grates manage surface water runoff, preventing flooding by allowing water to flow into drainage systems while blocking larger debris.

A: Manhole covers prevent accidental falls into underground spaces and protect infrastructure, ensuring safe access for workers and preventing unauthorized entry.

A: Manhole covers are often made from cast iron, ductile iron, or composite materials, designed to withstand heavy traffic and environmental conditions.