Views: 0 Author: Site Editor Publish Time: 2025-08-21 Origin: Site

The best manhole cover tools in 2025 are very strong. They are comfortable to use and have new designs. Many workers trust the Top Popper for taking off manhole covers. This tool uses heat-treated alloy steel. It has a big handle that fits gloved hands. The rocker head gives more power when lifting. People in septic service jobs say it works well and lasts long. These top manhole cover tools help workers stay safe and work fast. Picking the right tools makes the job easier and safer.

Top Popper: Big “D” handle, strong tip, rocker head, 88% good reviews

Use the correct manhole cover tool to stay safe. This helps you avoid getting hurt when lifting heavy covers. - Pick tools that match the cover’s size, weight, and material. This helps you work faster and makes lifting easier. - Choose strong tools made from tough materials like heat-treated steel or ductile iron. These tools last a long time. - Check, clean, and store your tools often. This keeps them safe and working well. - Think about your budget and what you need for the job. You can pick from manual, hydraulic, magnetic, or smart lifters.

Safety is the most important reason to pick the right manhole cover tool. Manhole covers are very heavy, from 90 to 250 pounds. Lifting them by hand is hard and can be dangerous. Using the wrong tool or lifting alone can hurt you badly. About 34 percent of work injuries are musculoskeletal disorders. Special manhole cover lifters have handles that are easy to hold or use magnets. These tools help workers lift covers in a safe way. Workers can use their body weight, not just their arms or back. A battery-powered manhole cover lifter was tested by real workers. It made lifting heavy covers easier and needed less force. This helps stop back injuries and keeps workers healthy. Experts say ergonomic manhole tools lower injuries, missed work, and expensive claims.

Tip: Always check the manhole area and wear safety gear before lifting.

The right manhole cover tool helps workers finish jobs faster. Ergonomic and smart tools make work easier and quicker. Studies show new manhole tools have load sensors and are made from light materials. These features help workers move covers fast and safely. OSHA says to use mechanical lifters to lower injury risk by up to 75%. When workers do not get hurt, they miss fewer days at work. This keeps projects moving. Companies that buy better manhole tools get more work done and have happier workers.

Ergonomic designs help workers remove manhole covers faster and with less pain.

Smart features, like IoT safety monitoring, help teams work better.

Mechanical aids help stop injuries and lower downtime.

Durability is important because manhole cover tools get used a lot. Tools made from strong materials, like heat-treated steel or reinforced composites, last longer. These tools do not bend, break, or rust easily. Workers trust these tools to lift heavy covers every day. When a tool lasts longer, it saves money and needs fewer replacements. Good manhole cover tools keep workers safe and help them do their jobs well every day.

The material used in a manhole cover tool is important. It helps decide how strong and long-lasting the tool is. Ductile iron is a top choice because it does not crack or rust. This makes it last longer and keeps workers safe. Ductile iron covers also have surfaces that help stop slipping. They can have locks for extra safety. Many manhole tools are made from cast iron, steel, or composite materials. Each material has its own good points.

| Material | Common Use Case | Benefits |

|---|---|---|

| Cast Iron | Heavy traffic areas, deep shafts | Very strong and tough, can hold up to 90 tonnes |

| Steel | Domestic driveways, walkways | Good for lighter jobs |

| Composite (Fiberglass Reinforced Plastic) | Harsh environments | Light, does not rust, does not conduct electricity, hard to steal |

Fiberglass is another good material. It does not rust or break down, even in bad weather. Fiberglass is light and easy to shape. It is also safe because it does not carry heat or electricity.

Ergonomic manhole tools help workers lift covers without getting hurt. Many tools have loop handles and foot levers for a better grip. Some tools use special handles or battery power to make lifting easier. Some tools can be used from far away. These features help stop back pain and other injuries.

Tip: Pick the right handle shape and length to lift safely.

Compatibility means a manhole tool works with many cover types. The right size helps stop accidents and damage. Some tools have lift rings that turn or pull back to keep covers steady. Special lift rings help with odd shapes or heavy covers. Grips that do not slip and easy-to-hold designs help workers use the tool longer.

Safety features help protect workers when taking off manhole covers. Workers should check their gloves, helmets, and harnesses before starting. Manhole cover lifters with turning handles or wrenches make lifting safer. Barriers around open manholes help stop falls. Push-pull tools help move covers without hurting fingers.

Always lift the right way.

Wear strong gloves.

Put up warning signs and barriers.

New manhole cover tools use smart ideas to make work safer and faster. Some tools have lever arms with wheels to help move covers easily. Magnetic lifters can pick up very heavy covers. All-in-one systems help workers take off and put back covers quickly. These new tools save time and help stop injuries.

There are a few main kinds of manhole cover equipment. Each type of manhole cover lifter has special features. These features make them good for certain jobs. The right tool keeps workers safe and helps them work faster.

Hooks and keys are used most often to lift manhole covers. Workers put these tools into the slots or holes of a manhole cover. The shape of hooks helps stop injuries and makes lifting easier. These tools work with many manhole covers, so they are very useful. Workers save time and do not get as tired when using them. Hooks and keys are strong and last a long time, even in rough places.

Tip: Hooks and keys are good for most lifting jobs and fit many cover shapes.

Magnetic lifters use strong magnets to stick to metal manhole covers. These lifters can pick up covers that weigh between 400 and 900 pounds. Workers like magnetic lifters because they are fast and simple to use. But, they only work on covers made from magnetic metals. The magnets can get weaker after a while.

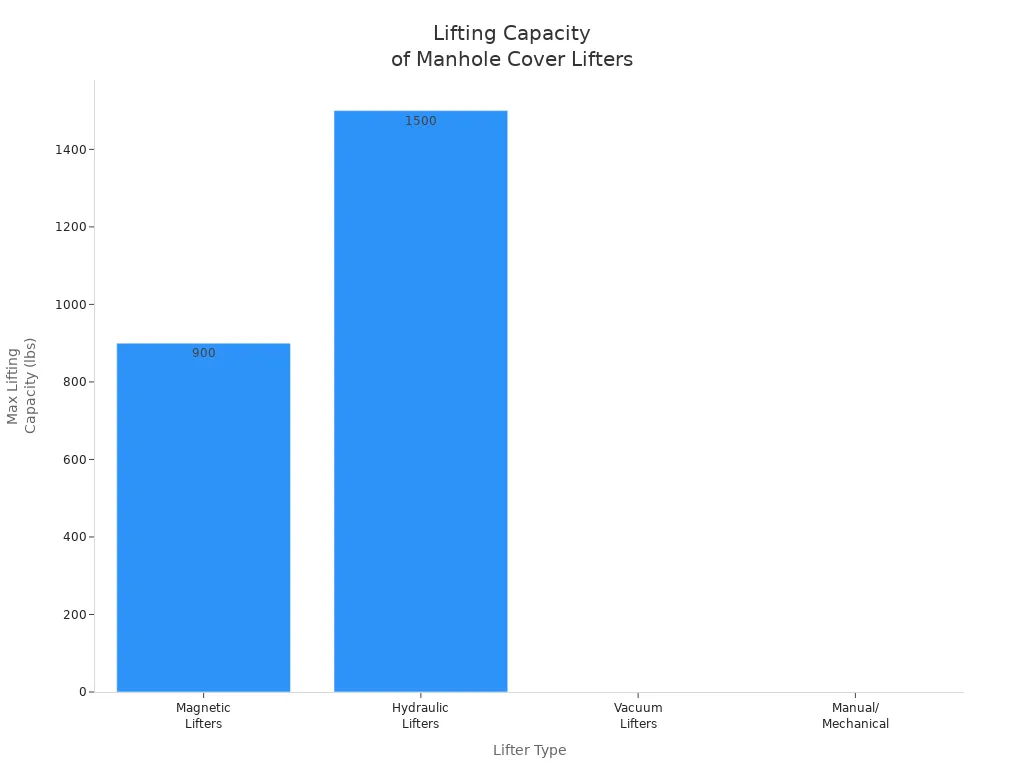

| Lifter Type | Lifting Capacity (lbs) | Key Features and Limitations |

|---|---|---|

| Magnetic Lifters | 400 - 900 | Fast, easy to use; only for metal covers; magnets may get weaker. Example: Allegro 9401-26 lifts up to 900 lbs (flat items). |

| Hydraulic Lifters | Up to 1,500 | Lifts very heavy covers; costs more and needs care. |

| Vacuum Lifters | Varies (non-metallic) | Lifts covers that are not metal; more complex and needs power. |

| Manual/Mechanical | Lower capacity | Good for lighter covers; needs more work from the user. |

Hydraulic lifters use suction and levers to lift very heavy covers. These lifters can handle up to 1,500 pounds. Workers do not need to match keys to slots, so it is safer and quicker. Hydraulic lifters close tightly, which stops noise and dirt. They are built strong and last a long time, even in bad weather.

Hydraulic lifters save time and make lifting easier.

They are best for big, heavy covers and jobs that need lots of lifting.

Fulcrum bars use a lever and a pivot to lift covers. The strong bar and lever arms give workers more power with less work. Wheels on the bar help move the cover safely. This makes fulcrum bars strong and steady for lifting heavy covers. Workers use fulcrum bars when they need extra strength or must move covers a short way.

Multi-purpose manhole cover tools can lift, pry, and move many kinds of covers, grates, and lids. These tools have different hook shapes and handles, like T-handles for a better grip. Workers use them for many lifting jobs, not just manhole covers. The flexible design lets workers do different jobs with one tool.

Note: Multi-purpose tools are great for teams who need to lift many types of covers in one day.

Choosing the best manhole cover tools in 2025 helps workers stay safe and work faster. The right manhole cover lifter can make a big difference for every job. Here are the top picks for different needs.

Top Popper Manhole Cover Lifter

The Top Popper stands out as the best manhole cover tool for most users in 2025. This tool uses heat-treated alloy steel and a large “D” handle. Workers find it easy to grip, even with gloves. The rocker head design gives more power for lifting heavy covers. Many crews trust this tool for daily use.

Pros:

Strong steel construction lasts a long time.

Ergonomic handle reduces hand strain.

Rocker head helps with tough covers.

Fits many manhole cover shapes.

Cons:

Still needs some physical effort.

Not ideal for the heaviest covers.

Note: The Top Popper gets high marks for safety and comfort. It works well for most city and utility jobs.

Bully Tools T-Style Hook

Professional crews often choose the Bully Tools T-Style Hook. This manhole cover lifter uses a T-shaped handle for better grip and control. The tool is made from thick steel, so it does not bend or break. It helps workers lift covers safely and quickly.

Pros:

Strong steel build for daily use.

T-handle gives good control.

Works with many cover types.

Reduces risk of back and hand injuries.

Cons:

Needs proper training for safe use.

Still involves some manual lifting.

Workers using outdated tools like pry bars face more injury risks. The Bully Tools T-Style Hook helps lower these risks. Crews need to learn the right way to use it and always wear gloves.

Cast Iron Manhole Cover Lifter

For those who want the best value, a cast iron manhole cover lifter is a smart choice. Cast iron tools cost less but still offer good strength and durability. Many city crews use these lifters for regular jobs.

Pros:

Affordable price.

Strong and long-lasting.

Meets safety standards.

Good for most lifting tasks.

Cons:

Heavier than some other options.

Needs regular checks for rust.

Buyers should look for lifters that fit their site needs and check for safety certifications. Regular inspection and care help these tools last longer.

Italifter Hydraulic Manhole Cover Lifter

Heavy-duty jobs need a tool with high lifting capacity. The Italifter hydraulic manhole cover lifter is the top choice for very heavy covers. This tool uses hydraulic power to lift covers that weigh up to 1,500 pounds. Workers do not need to match keys or use much force.

Pros:

Handles the heaviest covers.

Hydraulic system reduces strain.

Built from high-quality materials.

Ergonomic design for daily use.

Cons:

Higher cost than manual tools.

Needs regular maintenance.

Hydraulic lifters work best for cast iron and concrete covers. They keep workers safe and make lifting easier on big jobs.

Liftop Smart Manhole Cover Lifter

The Liftop brings new technology to manhole cover lifting. This tool uses sensors to track force and cover stability. It connects to mobile apps for real-time feedback. The lifter uses lightweight alloys and eco-friendly materials.

Pros:

Sensors improve safety and efficiency.

IoT features allow remote monitoring.

AI helps predict maintenance needs.

Lightweight and easy to carry.

Cons:

Costs more than basic tools.

Needs training to use all features.

Some smart manhole cover lifters even use solar power and connect to city systems. These features help workers spot problems early and keep covers safe.

| Tool Name | Best For | Lifting Capacity | Key Features |

|---|---|---|---|

| Top Popper | All-around | Up to 250 lbs | Rocker head, ergonomic handle |

| Bully Tools T-Style Hook | Professionals | Up to 200 lbs | T-handle, strong steel |

| Cast Iron Lifter | Budget | Up to 200 lbs | Affordable, durable |

| Italifter Hydraulic | Heavy-duty | Up to 1,500 lbs | Hydraulic power, ergonomic design |

| Liftop Smart Lifter | Innovation | Up to 300 lbs | Sensors, IoT, lightweight alloys |

Tip: Always match the tool’s lifting capacity to the cover’s weight for safe and easy lifting.

Picking the right manhole cover lifter starts with knowing the job. Workers should follow these steps to figure out what they need:

Find out what kind of manhole cover you have. Look at its material, size, and how much it weighs.

Make sure the lifter can hold as much or more than the cover weighs.

Choose a lifting tool that works for the cover. Magnetic lifters are good for metal covers. Hydraulic lifters help with very heavy covers. Mechanical lifters are best for lighter covers.

Pick a lifter made from tough materials. Good tools last longer and can be used every day.

Look for lifters that are easy to hold and move. Handles that adjust and tools that are simple to use help stop pain.

Train everyone who will use the lifter. Always follow the maker’s rules to stay safe.

Take care of the lifter. Clean it and check it often so it keeps working well.

Tip: Using the right lifter for the cover and job size helps stop injuries and keeps tools from breaking.

Workers need to pick tools that fit the job. They should look at the cover’s shape, size, and weight before choosing a tool. Some covers need magnetic lifters. Others need hydraulic or mechanical lifters. The best tool will have enough lifting power and fit the cover’s shape. Safety is important, so workers should block off the area and get permission before starting. Some tools, like the Italifters CL10 with a rectangle base, can do many jobs. Tools that last long and do more than one thing are helpful for different jobs.

| Feature | Best For | Example Use Case |

|---|---|---|

| Magnetic Base | Metal covers | Fast removal |

| Hydraulic Power | Heavy concrete covers | Large installations |

| Adjustable Handle | Ergonomics | Daily lifting tasks |

Money is important when picking a manhole cover lifter. The lifter must be strong enough for the cover or it could break or cause an accident. Buying a strong, easy-to-use lifter saves money because it lasts longer and helps stop injuries. Renting a lifter is smart for short jobs. It helps teams save money on storage and repairs. Taking care of the lifter by cleaning and storing it right makes it last longer and stops surprise costs. When planning to install a cover, workers should think about price, safety, and how fast they can work to get the best deal. Extra tools like lifters make the job easier, so teams should add them to the budget.

Note: Always check if the brand is trusted and if the tool is safe before buying.

Regular inspection keeps manhole cover tools safe and working well. Workers should check tools for cracks, chips, or signs of corrosion. They should look for misalignment and loose parts. Many teams set up inspection schedules every few months or once a year. Some use cameras or drones to spot problems without direct contact. Workers must always wear helmets, gloves, and high-visibility vests during inspections. They should test for hazardous gases before starting work. Teams should secure the area with cones and barriers to protect everyone nearby.

Check for cracks, rust, and loose parts.

Use cameras or drones for hard-to-see spots.

Wear safety gear and test for gases.

Block off the work area with cones and signs.

Tip: Always follow safety rules and train workers on inspection steps.

Clean tools last longer and work better. Dirt, leaves, and debris can cause damage if left on manhole covers or tools. Workers should use a brush or broom to remove loose dirt. For tough grime, a high-pressure hose works well. Cleaning also helps people see the covers better, which lowers the risk of accidents.

Sweep away dirt and debris with a broom.

Wash stubborn dirt with a hose.

Remove all materials that could cause rust or block the cover.

Clean tools after each use to keep them in top shape.

Safety comes first when handling manhole cover tools. Workers should always use the right tool for the job. They must wear gloves, helmets, and boots. Lifting should be done with the legs, not the back, and never alone. Workers should never put hands or feet under a cover. If a cover sticks, they can use a mallet to loosen it. Barriers around open manholes help prevent falls.

Use manhole pullers or hooks, not hands.

Wear heavy-duty gloves and safety gear.

Lift with legs, keep back straight.

Work with a partner for heavy covers.

Place blocks under lids after removal.

Set up barriers to keep the area safe.

Note: Training and awareness help prevent injuries and accidents.

Proper storage protects manhole cover tools from damage. Many tools have a compact design that fits inside service vehicles. Workers should store tools in a dry, secure place after each use. Keeping tools organized prevents loss and keeps them ready for the next job. Storing tools with their accessories also helps avoid damage.

Store tools in a dry, safe spot.

Keep tools and accessories together.

Use storage bins or racks in service vehicles.

Keeping tools stored well extends their life and keeps workers safe.

The best manhole cover tools in 2025 are the Top Popper, Bully Tools T-Style Hook, Italifter Hydraulic Lifter, Cast Iron Lifter, and Liftop Smart Lifter. Each tool is good for different jobs and budgets. People should pick the tool that matches their work. Safety, working fast, and new features are very important.

Look at the sections above before you buy. The right tool keeps workers safe and helps them finish jobs quickly.

Workers should always use a proper manhole cover lifter. They must wear gloves and safety gear. Lifting with the legs, not the back, helps prevent injuries. Two people should work together for heavy covers.

Teams should inspect tools before each use. They need to check for cracks, rust, or loose parts. Many companies set a schedule for deeper checks every few months.

No single tool fits every cover. Some covers need magnetic lifters, while others need hooks or hydraulic tools. Workers should match the tool to the cover’s material and shape.

They should use a mallet or a special loosening tool. Never use hands or feet to pry the cover. If the cover will not move, workers should call for help or use a hydraulic lifter.