Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

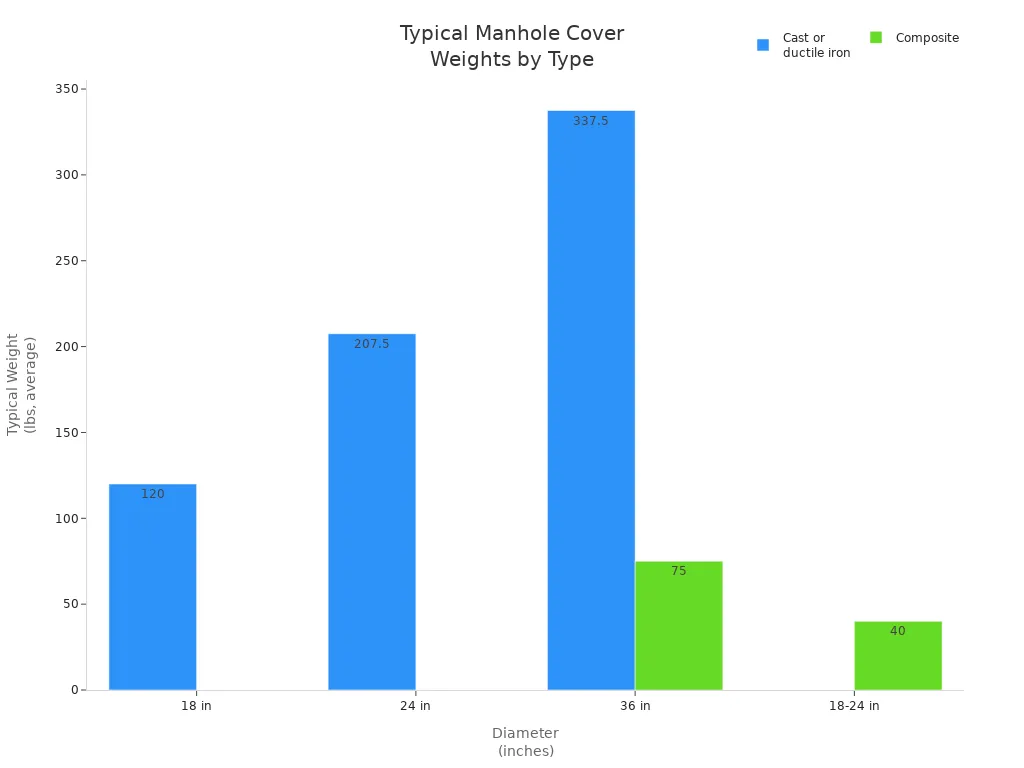

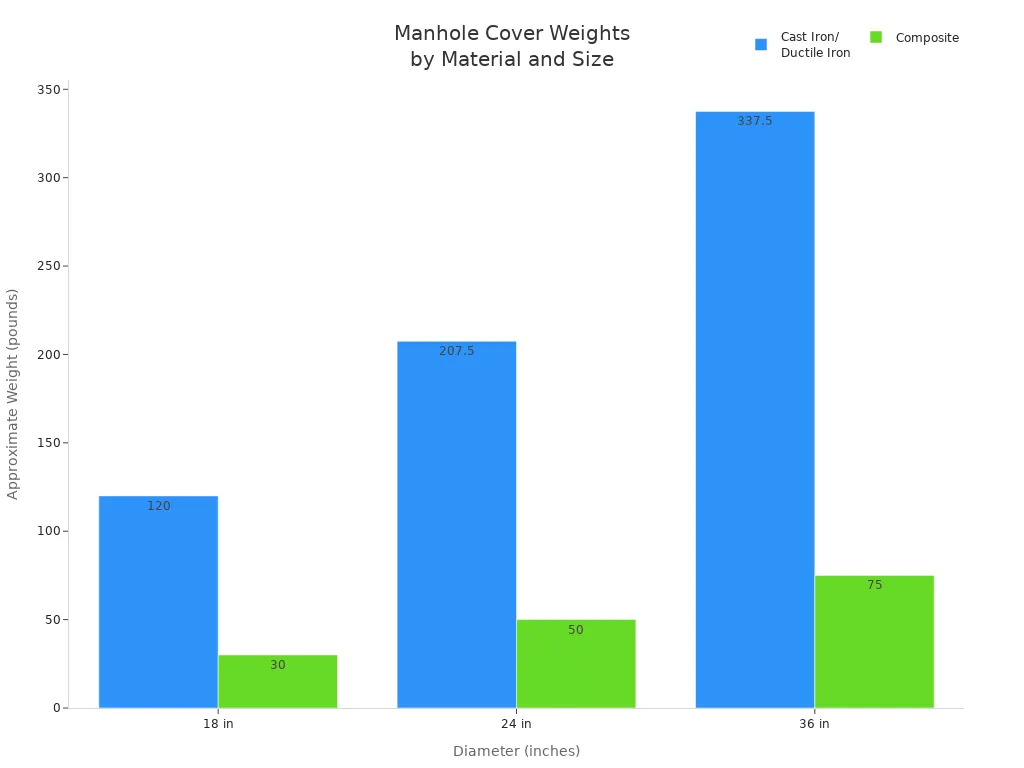

A standard manhole cover usually weighs between 90 and 250 pounds. The weight depends on its size and what it is made of. For example, a 24-inch cast iron cover can weigh 165 to 250 pounds. A composite cover of the same size may only weigh 40 to 60 pounds. The table below shows common weights for different materials and sizes:

| Diameter (inches) | Material Type | Typical Weight Range (lbs) |

|---|---|---|

| 24 | Cast Iron / Ductile Iron | 165 - 250 |

| 24 | Composite | 40 - 60 |

Manhole covers need to be heavy so they do not move by accident. This helps keep people safe and stops people from stealing them. The weight keeps the cover in place when cars drive over it. It also makes it hard for someone to take it without permission. Knowing how much a manhole cover weighs helps workers install them safely. It also helps people pick the right cover for each place.

Manhole covers often weigh from 90 to 250 pounds. Some heavy-duty and extra-large covers can weigh more than 300 pounds. The heaviest covers can even reach 600 pounds. The material of a cover changes how much it weighs. Cast iron covers are strong and heavy. Composite and fiberglass covers are much lighter. Lighter covers are easier for people to move. Heavier covers help keep roads and sidewalks safe. They stay in place when cars drive over them. Heavy covers also help stop people from stealing them. Lighter covers make it less likely for workers to get hurt. They also cost less to put in. Picking the right cover depends on its size, material, and load rating. These things must fit the traffic and safety needs of the area. Workers use special tools to lift heavy covers safely. Lighter covers help workers finish the job faster and safer.

How much a manhole cover weighs depends on its duty level and where it is used. Most standard covers weigh between 90 and 250 pounds. These covers are heavy so cars and trucks do not move them. Some heavy-duty covers weigh more than 300 pounds. Extra-large covers can weigh up to 600 pounds or even more. The weight helps stop the cover from moving or being stolen.

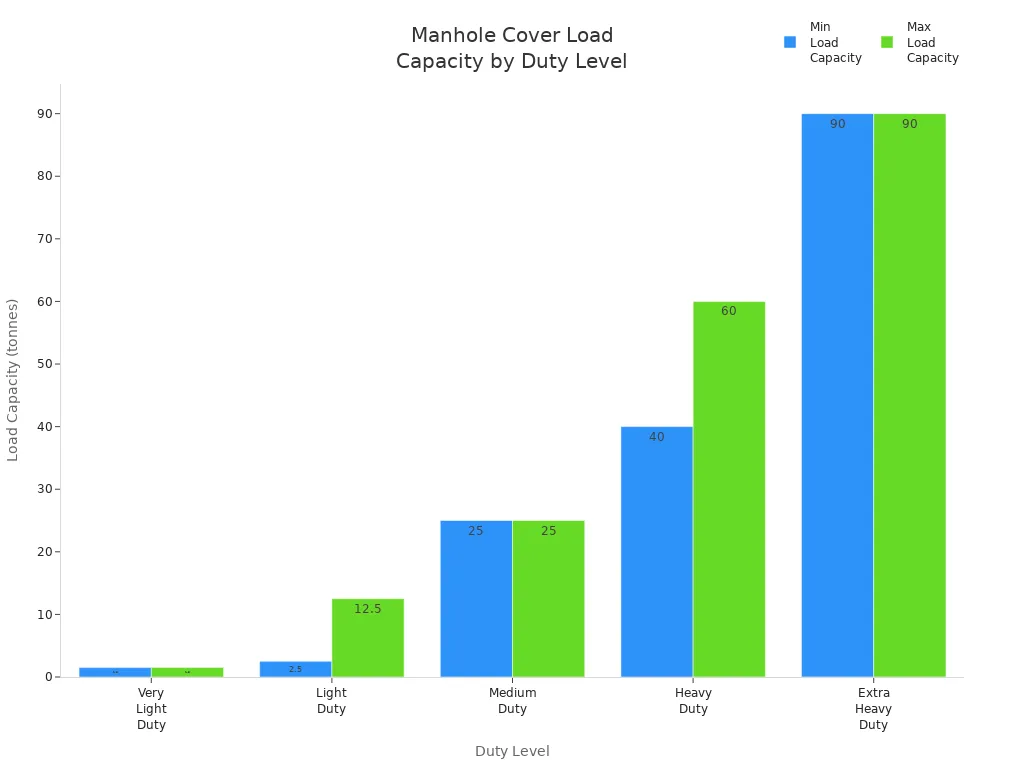

Manhole covers have different duty levels. Each level holds a certain weight and has its own job. Here is a table that shows the main duty levels, how much weight they hold, and where you find them:

| Duty Level | Load Capacity (tonnes) | Typical Use Cases |

|---|---|---|

| Very Light Duty | 1.5 | Patios, pedestrian areas, gardens, driveways |

| Light Duty | 2.5 - 12.5 | Pedestrian use, domestic driveways for cars, vans |

| Medium Duty | 25 | Small private car parks, lightly trafficked roads |

| Heavy Duty | 40 - 60 | Highways, main roads, public car parks, industrial estates, loading bays |

| Extra Heavy Duty | 90 | Airports, docks, extreme heavy-duty applications |

Most covers weigh more than 100 pounds. Heavy-duty and extra heavy-duty covers can weigh over 300 pounds. These covers protect busy places like roads, airports, and factories. As the duty level goes up, the covers get heavier.

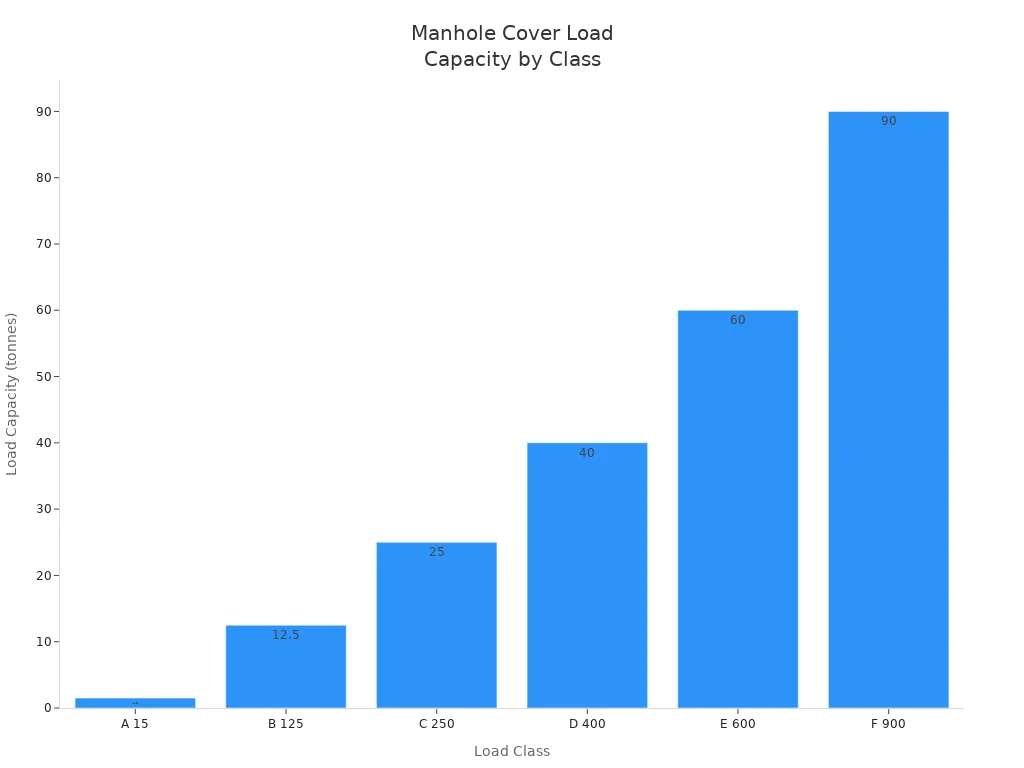

Different countries use different rules for manhole covers. In the United States, the AASHTO H-20 rule sets the load rating for most covers. This rule says covers must hold a single wheel load of 16,000 pounds. Other countries use the BS EN 124:2015 rules. These rules sort covers by loading class, like D400 for busy roads and F900 for airport runways. These systems help match the cover’s weight and strength to where it will be used.

Note: The weight of a manhole cover is not just about size. It also shows how much weight it can hold and how it keeps people safe.

The size of a manhole cover changes how much it weighs. A 24-inch cover is very common. Most 24-inch cast iron covers weigh between 165 and 250 pounds. Composite covers of the same size are lighter, usually 40 to 60 pounds. Bigger covers, like 36-inch ones, weigh even more. A 36-inch cast iron cover can weigh from 275 to over 400 pounds. Some extra-large covers, used in airports or docks, can weigh up to 600 pounds.

Here is a quick look at manhole cover weights by size:

24-inch standard covers: 165–250 pounds (cast iron), 40–60 pounds (composite)

36-inch standard covers: 275–400+ pounds (cast iron)

Extra-large covers: Up to 600+ pounds

Most covers for roads and highways weigh more than 100 pounds. Heavy-duty covers for factories or airports can weigh much more. As covers get bigger, they also get heavier.

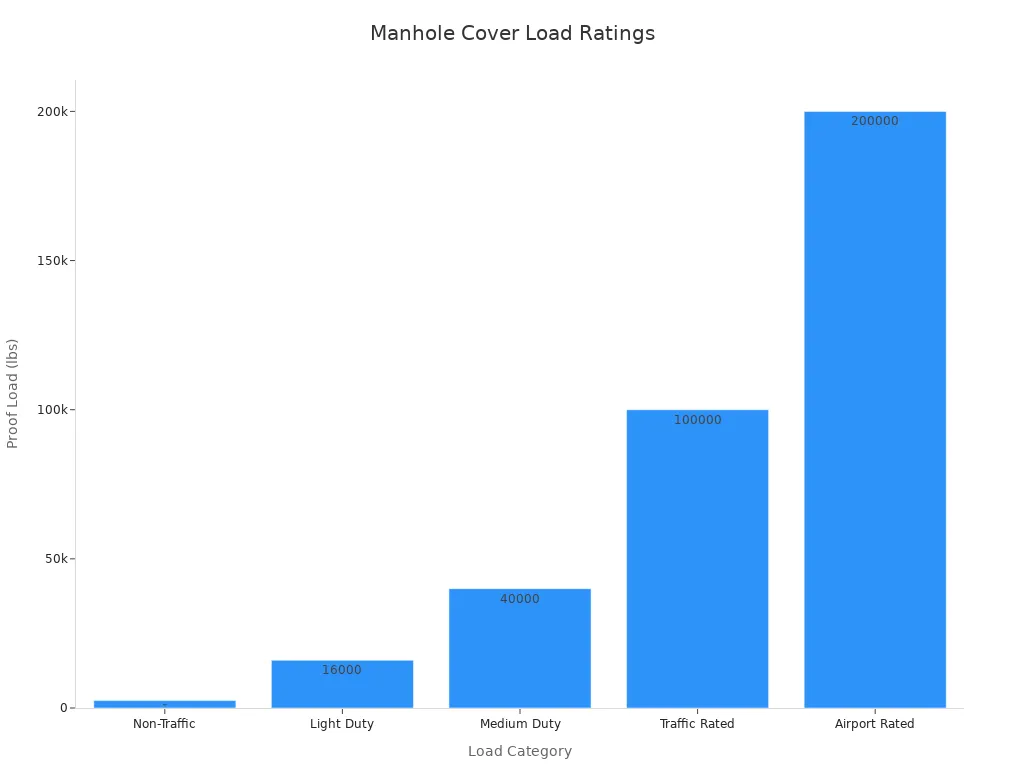

The next chart shows how much weight each class of manhole cover can hold. Bigger and heavier covers can hold more weight and are used in busier places.

The weight of a manhole cover is important for how it works. Standard covers are good for most city streets. Heavy-duty and extra-large covers are needed for places with lots of traffic or special machines. Knowing these weight ranges helps workers pick the right cover for each job.

Cast iron and ductile iron covers are used in most cities. These covers are very strong and can hold heavy cars and trucks. The weight depends on the size and where it is used. In towns, medium-duty covers weigh about 33 to 110 pounds. Heavy-duty covers can be much heavier, up to 440 pounds for big ones. Both materials weigh about the same because they do the same job.

| Material | Shape | Size (inches) | Weight (kg) | Typical Use |

|---|---|---|---|---|

| Cast Iron | Square | 10 x 10 | 2.5 | Earthing Chamber Cover |

| Cast Iron | Round | 30 x 30 | 50 | Heavy Duty Construction |

| Ductile Iron | Rectangular | 24 x 18 | 15 | Medium Duty Construction |

| Ductile Iron | Round | N/A | ~50 | Heavy Duty / Municipal Use |

These covers are heavy, so workers need special tools to lift them. Cast iron and ductile iron covers last for years and are good for busy roads.

Composite and FRP covers are much lighter than cast iron covers. They are about one-third lighter than iron covers. This makes them easier to move and put in place. One worker can often lift a composite cover alone. This helps stop injuries. These covers do not rust and last a long time, even in wet places.

Composite covers are light, so they are faster to install.

FRP covers are safe for roads and sidewalks.

Lighter covers cost less to move and fix.

Composite covers are used in sewers, drains, and places with lots of water. They help cities save money and keep workers safe.

Steel and concrete covers are used for special jobs. Steel covers are strong and come in many shapes and sizes. They are heavy and need a coating to stop rust. Workers need special tools to lift steel covers. Concrete covers are even heavier and can break if not handled right. Machines are often needed to put concrete covers in place.

| Material | Typical Diameter (inches) | Approximate Weight (pounds) | Handling and Installation Impact |

|---|---|---|---|

| Steel | Varies | Heavy | Needs coatings and lifting tools |

| Reinforced Concrete | Varies | Very heavy | Needs machines for handling |

Concrete covers last a long time and look like the road or sidewalk. Steel covers are good for places that need special shapes or extra strength.

Note: How much a manhole cover weighs changes how easy it is to put in and fix. Lighter covers like composite and FRP types help stop injuries and make changing them easier.

Many things change how much a manhole cover weighs. Knowing these things helps workers pick the right cover for each job. The main things that change the weight are material type, size and thickness, and load rating.

What a cover is made from is very important. Different materials have different weights and strengths. Cast iron covers usually weigh between 175 and 300 pounds. This is much more than the 50-pound lifting limit set by OSHA. Heavy covers can hurt workers’ backs. Composite and fiberglass covers are much lighter. They can weigh only one-third or even one-tenth as much as concrete or cast iron covers. Lighter covers are easier and safer for workers to move.

| Material Type | Typical Weight Range | Weight Influence and Impact |

|---|---|---|

| Cast Iron | Around 249 pounds or more | Very heavy; traditional material causing handling and safety issues |

| Concrete | Similar to cast iron | Heavy, difficult to handle |

| Composite | Up to one-third lighter | Significantly lighter, easier to handle, reduces injuries and costs |

| Fiberglass | As little as one-tenth concrete | Extremely lightweight, easier installation and handling |

| Plastic | Lightweight | Alternative to heavy traditional materials |

How big and thick a cover is also matters. Bigger covers have more surface area, so they weigh more. For example, a 600mm cover is heavier than a 500mm cover. The area gets bigger fast as the diameter grows. Thicker covers are needed where there is lots of traffic. These covers must be strong to hold up cars and trucks. That is why they are made thicker and heavier. Both size and thickness are important for manhole cover weight.

Tip: Bigger and thicker covers are used where there are more cars or trucks.

Load rating means how much weight a cover can safely hold. This is another big thing that changes the weight. Covers with higher load ratings must be stronger and heavier. For example, covers for highways or airports are much heavier than covers for parks or sidewalks. The table below shows how load rating changes the design and weight:

| Load Rating Category | Traffic Condition Suitability | Material Impact on Weight and Durability |

|---|---|---|

| Light-Duty | Pedestrian areas, green spaces | Generally lighter, less reinforcement needed |

| Medium-Duty | Parking lots, occasional vehicle traffic | Lighter weight, less reinforced, suitable for low-volume traffic under 25 MPH |

| Heavy-Duty | Roads, highways, continuous heavy traffic | Heavier, extra reinforcement, designed for higher traffic volumes and heavier vehicles |

| Extra Heavy-Duty | Airports, freight terminals | Heaviest, maximum reinforcement, designed for extreme load conditions |

Covers with higher load ratings last longer and need less fixing. They are made to handle tough places and keep people safe.

Manhole cover weight is important for safety. Heavy covers keep roads and sidewalks safe. E600 and F900 covers are very heavy. They can hold up to 60 or 90 tonnes. These covers are used in busy places like airports and ports. The extra weight keeps them from moving when trucks drive over them. Ductile iron covers are strong and do not crack easily. Many heavy covers have ribbed bottoms and special coatings. These coatings stop rust and damage. This makes the covers last longer and stay strong.

Heavy covers can handle big loads in busy places.

Their weight keeps them from moving or breaking.

Ductile iron makes covers strong and tough.

Special coatings protect covers from rust and harm.

The weight stops covers from shifting or being stolen.

International rules make sure covers are safe.

Note: Each manhole cover is tested before use. This makes sure it is safe and strong enough.

Heavy manhole covers are hard to steal. Thieves like lighter covers because they are easy to carry. Heavy covers make stealing much harder. Cities use heavy covers where theft is a problem. This keeps people safe and saves money on new covers.

Manhole cover weight changes how workers put them in. Heavy covers, like those weighing 275 to 400 pounds, need special tools. Workers use crowbars or lifting keys to move them. These tools help stop injuries. Lighter composite covers are easier to lift and install. They work best in places with less traffic. No matter the weight, workers must level the frame and secure the cover. Heavy covers stop movement and theft but cost more to install. They need more tools and workers.

| Aspect | Details |

|---|---|

| Weight Comparison | SMC composite covers weigh about 25% of cast iron covers of the same size |

| Cost Impact | Transportation and installation costs reduced by approximately 40% due to weight savings |

| Handling & Installation | Easier handling, less need for heavy lifting equipment, faster installation |

| Shipping Logistics | Safer and more reliable shipping; global, reliable delivery with tracking available |

The cost of cover weight is easy to see. Lighter covers cost less to install and move. Heavy covers are safer and last longer. But they cost more to put in because they need special tools and more workers.

Manhole covers can weigh as little as 40 pounds. Some heavy-duty cast iron covers weigh over 400 pounds. The weight depends on the material and size. Picking the right cover helps keep people safe. It also protects roads and things under the ground. Lighter composite covers are good for sidewalks and walking paths. Heavy cast iron covers are better for busy roads. City planners now look for covers that are strong and easy to move. They want covers that last a long time and are not too hard to handle.

Always pick a cover with the right weight and material for where it will be used and how much traffic it will get.

Workers use special tools like cover hooks or keys. These tools help stop injuries. Sometimes, teams use small machines for very heavy covers. Safety training shows workers how to avoid getting hurt.

Composite and fiberglass make covers lighter. These covers weigh much less than cast iron or concrete. Workers can lift them more easily. Lighter covers also cost less to install.

Cities pick round, square, or rectangular covers for different reasons. Round covers cannot fall through their holes. Square and rectangular covers fit special spots. Each shape has its own job.

Cast iron and steel covers can rust over time. Composite and fiberglass covers do not rust. Concrete covers can crack if dropped. Regular checks help find damage early.

Engineers and city planners pick covers based on traffic and safety. They follow rules for load ratings and materials. Their choices keep people and property safe.